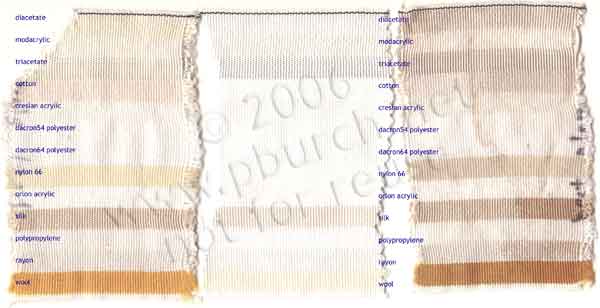

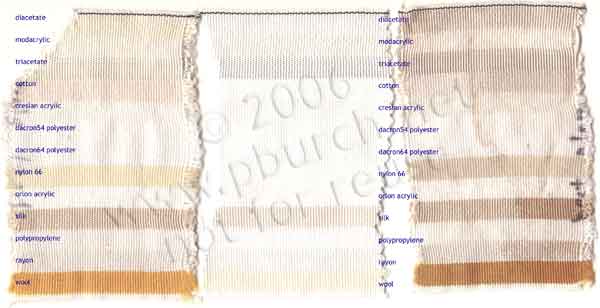

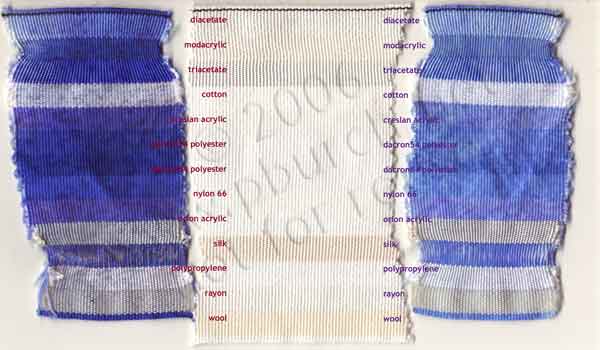

The testing fabric used was a multi-fiber ribbon, 4 inches wide, containing 13 different fibers, manufactured by TestFabrics, Inc. (415 Delaware Avenue, PO Box 26, West Pittston, PA 18643; phone 717-603-0432; fax 717-603-0433), their "Warp Stripe 13 Fiber Fabric". The fabrics are, in order (starting with the black stripe at the top, or from the left side of the chart):

Unmordanted samples (except for disperse dye) are indicated by an upper corner cut from the swatch. The mordanted samples were treated by boiling in a 25% by weight of fabric solution of alum (purchased from Aurora Dyes) then cooling overnight. (Note that cotton is better mordanted by treating with alum, then tannic acid, then alum again.) Each swatch is shown with an undyed control swatch. Note that the different undyed fibers are not all perfectly white. The dye intensity was obtained by subtracting the luminosity for a representative section of each fiber strip (avoiding shadows and light spots due to air bubbles during dyeing) from the same value for the corresponding undyed control. Since scans made at different times may vary somewhat in darkness or contrast, every scan included the control, and only the control values from the same scan were used.

All of the dyeing, except for the basic conditions for Procion MX dye and the disperse dye application,, was performed with 1 tablespoon of vinegar per 375 ml. Each swatch was placed in a glass canning jar containing the dyebath and placed in a pot of water which was started cold, brought to a boil, boiled for twenty minutes, then allowed to cool overnight. after the jars were removed from the boiling water bath. The Procion MX acid conditions swatches were treated as above. The Procion MX basic conditions used the exact same dye amount, from the same dye concentrate, asfor the Procion Mx acid conditions, but dyeing was done at room temperature with 5 ml sodium carbonate per 375 ml dyebath. The disperse dye, unlike all others, was not tested with a mordant. A blue Crayola brand fabric crayon was colored onto paper, once heavily and once somwhat lighter, and transfered with a hot dry iron to the fabric swatches.

All of the dye swatches were rinsed after dyeing in cool water, and then laundered in a lingerie bag in hot water with Synthrapol detergent.

On silk an adequate beige was obtained only with the alum mordant. On wool, a good orangish tan was achieved without the mordant, and a darker tan with the alum premordanting. All other fibers either stayed white or acquired at most a pale stain.

Note the pale air bubble on the upper right third of the alum-mordanted swatch (on the right). Alum was of considerable assistance in dyeing rayon and cotton. Nylon, silk, and wool all dyed very well without mordant and even better with it.

Mordanting made no difference at all to the performance of Procion MX dye.

Cellulose fibers did not dye at all with Procion MX dye under acid conditions; neither did the synthetic fibersdyes other than nylon.

Nylon 66, silk, and wool all love Procion Blue MX-R (reactive blue 4) under hot acid conditions.

Interetsingly, Diacetate picked up a pale but unmistakable pink color when dyed with Procion MX dye under hot acid conditions. It must be binding to the chromophore section in order to affect the color.

What appears to be a slight color shift on silk and wool turns out on closer examination to be merely the effect of the yellower starting color of the undyed fibers. Only dyes which are mixtures of two or more colors show a true color shuift on different fibers, but such a color shift can be quite pronounced, due to different affinities of the different dye colors for the different fibers.

Silk loves dye. Cochineal and acid Mx are the best, but basic MX and turmeric are intense, too.

Cotton prefers basic MX. Cotton also likes cochineal and turmeric, but only if they are mordanted.

Rayon, like cotton, likes mordanted cochineal, basic MX dye, and mordanted turmeric. (Rayon is a synthetic fiber, but it is a true cellulose fiber and thus closely resembles mercerized cotton.)

Nylon loves acid dyes (including cochineal and acid MX) and also disperse dyes.

All of the synthetic fibers except for nylon and rayon like disperse dye the best, and mordanted turmeric somewhat.

Advertisements