« 2012 July | Main | 2012 May »

Saturday, June 30, 2012

My studio can get very hot. Will temperatures of 100 degrees harm my Tinfix dyes?

from a master

DVD: Silk Painting

With Jill Kennedy

Silk Painting: The Artist's Guide to Gutta and Wax Resist Techniques

by Susan Moyer

Country or region: North Carolina, USA

Message: My studio can get very hot. Will temperatures of 100 degrees harm my Tinfix dyes? Did look for this on your site and could not find an answer. Thanks.

Friday, June 29, 2012

How do I make pink for tie dye?

Linda Johansen's book

Fabric Dyer's Dictionary

shows how to mix a small number of Procion dyes to obtain a large number of different solid colors

Country or region: New Mexico

Message: How do I make pink for tie dye? Don't want to wait til the fourth for a new Dharma delivery.

Wednesday, June 27, 2012

How can I dye my 100% cotton blouses without a washing machine?

5 Gallon Bucket w/Measurements

A five-gallon bucket is ideal for immersion-dyeing a pound or so of clothing

24" Plastic Stirring Spoon

You'll need a long-handled spoon to stir with. It should be plastic or stainless steel, and not shared with your cooking utensils. A long wooden spoon will work, but only once, since it absorbs the color.

Sure. Washing machine dyeing shouldn't ruin other clothing, if you run a wash cycle afterwards to wash out your newly-dyed clothes, and make sure to wipe out any splashes of dye that occur above the waterline, but it could be uncomfortable to dye in a group washing machine.

You can use a five-gallon plastic bucket to dye up to one and a half pounds of clothes a single color (weighed while dry). Five gallon buckets are sometimes given away free by restaurants or delis, still dirty and needing to be washed out, and are sold pretty cheaply at hardware stores. You will also need a long-handled spoon, either plastic or stainless steel, long enough to reach the bottom of the bucket and have enough sticking out to keep your hands out of the dye. Gloves are a good idea.

Do not use all-purpose dye, such as Rit brand dye. All-purpose dye is drastically inferior in quality, bleeds in the laundry every time you wash it, and is a real pain to apply, too, since it works best in boiling hot water.

Instead of Rit, buy some Procion MX dye, which is a type of fiber reactive dye. It's superior in every way to all-purpose dye, lasts a hundred times longer, and doesn't require hot water. In the northeast a good online source is PRO Chemical & Dye. You can also buy it from a store in Manhattan called Aljo Mfg., in person or by telephone order.

Tuesday, June 26, 2012

How can I dye shirts by floating dye on the surface of water to get a marbled effect?

Country or region: Michigan, US

Message: Good morning, I found your site through google search, I have to say it's amazing. I'm trying to figure out how to dye shirts(cotton tank tops or wife-beaters) by floating the dye on the top of the water, to get a marble effect. I've tried every search I can think of and I'm getting nothing. Is there a name for that type of dying? Do you have any idea how to do it? I want it to be similar to the Easter egg kits you can get, the dye floats on the water and you put the egg in and it comes out marbled. Hope you can help, we are looking to do this for my daughter's baton team and I want it to look just right.

Saturday, June 23, 2012

I need to know if I can use both food coloring and regular color dye for a cotton sheet just to make the color darker?

Country or region: United States

Message: I need to know if I can use both food coloring and regular color dye for a cotton sheet just to make the color darker???? Thank you for your time...

Even with all the many advantages of Procion dye over all-purpose dyes such as Rit, all-purpose dye is still a tremendously better choice than food coloring, for coloring or darkening a cotton sheet. All-purpose dye will fade and bleed and no longer look as fresh after several washes, but that is much, much better than the way food coloring fades out immediately! At least you get some use out of it before it fades.

If you want dark colors while using Rit dye, you should increase both the amount of dye and the amount of heat. Rit is a hot water dye and works best when simmered for an hour with your sheets or clothes in a very large pot of water and salt, stirring constantly. For a medium shade, you can use one-half to one box of Rit to dye half a pound of cotton sheeting; use more for darker colors, or less for pale colors. Since your sheets weigh more (dry) than 8 ounces, you have to use several boxes of dye, one to two boxes for every pound of fabric, in order to get a medium shade. Weigh yourself with and without all of the sheets you're dyeing, to get an idea of how many pounds the sheets weigh. For dyeing three pounds of sheets to a medium color, use 3 to 6 boxes of Rit dye. (Your local sewing or crafts store probably won't carry many of any single color in stock, so you may have to drive from store to store to buy enough; ordering easier-to-use, more economical, and more beautiful Procion dyes online is sounding better and better!)

For dark shades, you must double or triple the amount of dye you add, so, for example, three pounds of 100% cotton sheets will require not just 6, but 12 to 18 boxes of Rit dye. You can buy just one large jar of superior Procion dye for far less than the cost of thirty boxes of Rit, even including the cost of shipping.

Conclusion: save your food dye for coloring food, or dyeing wool yarn or silk scarves, or even your own hair. Rit dye is much better than food coloring, when you're dyeing cotton, but you'll probably need to invest in a large number of little boxes of dye, and, ideally, acquire a 3-or 4-gallon non-aluminum cooking pot for using hot-water dyes in. Procion MX dye is better, cheaper, and easier to use; it's only drawback is that you must order it online. Try ordering from Dharma Trading Company if you're on the west coast, Grateful Dyes in Colorado, or PRO Chemical & Dye on the east coast, or see my list of Sources for Dyeing Supplies Around the World.

(Please help support this web site. Thank you.)

Monday, June 18, 2012

Country or region: Wisconsin

Message: I am tye dyeing with 200 kids at my campground. I don't see info in dyeing in big buckets for a non-toxic mix on cotton shirts. I need help. I'm in a time crunch!

Saturday, June 16, 2012

Country or region: Pennsylvania, USA

Message: Is it possible to dye a silk velvet burnout dress with a completely sewn-in rayon liner? It is currently a cream color (and marked dry clean only). I was hoping to get it to a fairly rich brown.

Unfortunately, all of this dyeing advice depends utterly on successfully washing the dress first, in spite of the dry-clean-only label. You can't dye anything without washing it first, and there is a very real chance that washing will destroy this dress.

(Please help support this web site. Thank you.)

Friday, June 15, 2012

What is the best method and dye to dyeing crochet cotton threads to get really vibrant colors, both solid and rainbow?

Linda Johansen's book

Fabric Dyer's Dictionary

shows how to mix a small number of Procion dyes to obtain a large number of different solid colors

Country or region: USA

Message: Hi, I got your site from Marilee Rockley. I am most interested in dyeing my crochet cotton threads myself to get really vibrant colors, solid and rainbow. What is the best method and dye for that project? Would the thread have to be unwound and skeined to dye it? Heat treated? I have never dyed anything really, and would love to be educated. Thank you for your time to my questions.

Thursday, June 14, 2012

Does ProChem have an equivalent to Dharma's Fire Red or Avocado Procion dyes?

Linda Johansen's book

Fabric Dyer's Dictionary

shows how to mix a small number of Procion dyes to obtain a large number of different solid colors

Country or region: USA

Message: I looked to see if you have a match for Dharma FIRE RED and AVOCADO on Pro Chem and Dye. I live on the east coast and shipping is killing me. I am in love with those colors though. I need to buy asap to teach a class. I have heard good things about Chinese red which has a mate with Pro chem...but I really love the FIRE RED and i am scared it will be a big change.

I am also having a hell of a time with black. I do a penguin design that is mostly black. I use squirt bottles and wonder...I have never done a vat dye...I also worry the stuff I think recommended on here has to be warm..but I keep mine refrigerated. So...

Wednesday, June 13, 2012

Please let me know whether Drimarine K dyes are monofunctional or bifunctional.

John Shore's

Cellulosies Dyeing

Useful information about the chemistry of reactive dyes, and other dye types used for cotton and other plant fibers

Victor B. Ivanov's

Reactive Dyes in Biology and Medicine

Explains use of reactive dyes for staining proteins or carbohydrates

Country or region: Pakistan

Message: Please let me know whether Drimarine K dyes are monofunctional or bifunctional.

For a drawing of the reaction between a representative Drimarene K dye and a textile fiber, see my blog post from February 21, 2006.

(Please help support this web site. Thank you.)

Friday, June 08, 2012

Can you give me some advice on how to dye both fabrics in a polyester lace dress lined with cotton?

Enameled canning pots make good dyeing kettles

Columbian Home 33-Quart Jar Canner and Rack

Holly Brackmann's book

The Surface Designer's Handbook

includes directions for dyeing with disperse dyes

Country or region: USA

Message: I have a dress (yes I know, I read your post about dying formal dresses), but this is not dry clean only. It is a lace made of polyester over a 97% cotton fabric. The fabric is visible through the polyester lace. I am very invested in dying this dress, can you give me some advice on how to make a uniform dye of the polyester and the cotton? It is hot pink now, I would prefer literally any other color. I though navy blue or black might cover nicely. Thank you for your help.

Wednesday, June 06, 2012

Can I dye shorts that are 85% nylon and 15% elastane with a polyester lining?

Country or region: Canada

Message: I have shorts that are 85% nylon and 15% elastane with a polyester lining. I want to tie dye them but I'm not sure it will work or what die to use. Do you have any suggestions?

(Please help support this web site. Thank you.)

Monday, June 04, 2012

What kind of dye goes on clear and develops under sunlight?

by Suda House

Message: Hi! In the 70's and 80's I used a fantastic fabric dye. I could free paint with this dye. It went on clear and had a slight thick consistency. I would set it out in the sun, or under a sun lamp, and the paint would transform into quite vibrant colors. I cannot remember the name but do know they were based out of Oakland (maybe San Francisco) Calif. Can you help me??? Thanks Cindy!

(Please help support this web site. Thank you.)

Sunday, June 03, 2012

How can I lighten dark blue shirts to light blue, without damaging the yellow iron-on logos

Country or region: USA

Message: I have some dark blue tee shirts that I would like to lighten to a light blue but am unsure what product to use to do this. They are work shirts so I don't want to screw them up! They are 100% ultra cotton and there is a bright yellow logo on the front that appears to be iron-on that I also do not want to damage. Thank you for your time.

My studio can get very hot. Will temperatures of 100 degrees harm my Tinfix dyes?

Name: Joanna

—ADVERTISEMENTS—

Learn silkpaintingfrom a master

DVD: Silk Painting

With Jill Kennedy

Silk Painting: The Artist's Guide to Gutta and Wax Resist Techniques

by Susan Moyer

Country or region: North Carolina, USA

Message: My studio can get very hot. Will temperatures of 100 degrees harm my Tinfix dyes? Did look for this on your site and could not find an answer. Thanks.

While the MSDS for Tinfix Design Silk Dye [PDF] says "Stable under normal storage condition" and "Avoid heat", I think your dyes should probably stay good at least in the short term.

Tinfix dyes are one of several available brands referred to collectively as the French Silk Dyes, which seem to be mostly composed of acid dyes or basic dyes, along with various chemical solvents such as ethanol. (It's not easy to know what types of dyes are in them, because the manufacturers are extremely secretive about which dye chemicals they use.) Although reactive dyes, such as Procion MX dyes, will go bad after a couple of years and go bad more quickly when stored in a hot place, acid dyes and basic dyes, since they have no reactive group to go bad, are more resistant to heat damage and will probably stay good for many years as long as no evaporation of the solvent occurs. Even Procion MX dyes can still function well as acid dyes, when used with acid on a protein fiber, long after they have lost their reactivity and can no longer be used on cotton.

Letting the dyes get really hot, near a heater for example, could be hazardous because of the flammable solvents, but that's very different from your studio temperature around 100°F.

What's surprisingly more important than avoiding a hot studio is avoiding an extremely cold one. The MSDS for Tinfex Dye Thinner says not to store it below 10°C, that is, 50°F. I would guess that low temperatures, as long as they do not get as low as freezing, would be a problem only because most dyes are less soluble when cold than when they are at room temperature.

It would be a good idea, whenever you have not used your dyes for a while, to do a small test from each bottle, to make sure they're still working fine. Use a small scrap of the same material that you are painting on, and steam it to fix. Problems are more likely to occur in the consistency of the dye mixture than in how well it steams.

Always be careful to keep all French silk dyes, and everything you have painted with them, out of direct sunlight, and store them in the dark whenever possible. They are noted for being susceptible to light damage, probably because some of them contain basic dyes (also known as cationic dyes). Basic dyes are notoriously poorly lightfast, and can lose their brightness quickly when exposed to bright light. This is true not only of ultraviolet light, but also of ordinary visible light.

(Please help support this web site. Thank you.)

(Please help support this web site. Thank you.)

Friday, June 29, 2012

How do I make pink for tie dye?

Name: Chuck

—ADVERTISEMENTS—

Linda Johansen's book

Fabric Dyer's Dictionary

shows how to mix a small number of Procion dyes to obtain a large number of different solid colors

Country or region: New Mexico

Message: How do I make pink for tie dye? Don't want to wait til the fourth for a new Dharma delivery.

Pink is just a light red, obtained by using a much smaller amount of dye powder per squirt bottle. Use about a tenth as much red or magenta dye powder as you normally would when mixing a bright red dye for tie-dyeing. If you normally use one tablespoon of fuchsia or red dye powder per cup of water for an intense bright color, use a quarter teaspoon of dye powder per cup, for a pale pink. The amount of dye powder you use determines the intensity of your pink. Use only an eighth of a teaspoon of dye powder for an even paler color, or half a teaspoon for a pink that's not quite as pale.

There are different pinks you can make, too. The pink you will get by using a small amount of fuchsia is pretty much a bubble-gum sort of pink, which is a somewhat bluer color than the pink you will get by using a small amount of a true red dye mixture. Try using a similarly small concentration of bright orange for a nice pale peach color.

The pre-mixed pink Procion dyes you can buy contain a neutral powder diluant so that you can measure a larger volume and still get a pale color. Mixing your own pale colors by using less dye powder will save you money.

(Please help support this web site. Thank you.)

(Please help support this web site. Thank you.)

Wednesday, June 27, 2012

How can I dye my 100% cotton blouses without a washing machine?

Country or region: New York, NY

—ADVERTISEMENTS—

5 Gallon Bucket w/Measurements

A five-gallon bucket is ideal for immersion-dyeing a pound or so of clothing

24" Plastic Stirring Spoon

You'll need a long-handled spoon to stir with. It should be plastic or stainless steel, and not shared with your cooking utensils. A long wooden spoon will work, but only once, since it absorbs the color.

Message: I'm thinking about dying a few blouses; they're white, 100% cotton. My concern is that I don't have a washer/dryer in my apartment, and I'm a bit leery of using the ones in the building for a project like this; I don't want to be the neighbor who was responsible for dyeing someone's underpants purple. Can I do this without a washing machine?

Sure. Washing machine dyeing shouldn't ruin other clothing, if you run a wash cycle afterwards to wash out your newly-dyed clothes, and make sure to wipe out any splashes of dye that occur above the waterline, but it could be uncomfortable to dye in a group washing machine.

You can use a five-gallon plastic bucket to dye up to one and a half pounds of clothes a single color (weighed while dry). Five gallon buckets are sometimes given away free by restaurants or delis, still dirty and needing to be washed out, and are sold pretty cheaply at hardware stores. You will also need a long-handled spoon, either plastic or stainless steel, long enough to reach the bottom of the bucket and have enough sticking out to keep your hands out of the dye. Gloves are a good idea.

Do not use all-purpose dye, such as Rit brand dye. All-purpose dye is drastically inferior in quality, bleeds in the laundry every time you wash it, and is a real pain to apply, too, since it works best in boiling hot water.

Instead of Rit, buy some Procion MX dye, which is a type of fiber reactive dye. It's superior in every way to all-purpose dye, lasts a hundred times longer, and doesn't require hot water. In the northeast a good online source is PRO Chemical & Dye. You can also buy it from a store in Manhattan called Aljo Mfg., in person or by telephone order.

Here's a link to a good set of instructions for dyeing in a bucket, and here's another, "Immersion Dyeing USing PRO MX Reactive Dyes" [PDF]. You'll need dye powder, soda ash or washing soda (buy with your dye), and a large quantity of salt.

All of the above is for dyeing a single solid color, which requires a lot of water and a lot of stirring. A much easier form of dyeing involves putting a blouse in a smaller container, scrunching it up first, and pouring the same type of dye and only a small amount of water over it, only enough to barely cover the fabric, then pouring over a little dissolved soda ash and leaving it to react. No stirring is required. This method is called low water immersion dyeing, and it creates a more interesting multi-shade or multi-color effect, though much subtler than tie-dyeing. For instructions, see How to Do Low Water Immersion Dyeing.

After you're done dyeing, there's a lot of unattached excess dye that has to be washed out. Wash first in cool water, then wash twice in very hot water, if the clothing can handle it. After this initial washing is completed, it's safe to wash different-colored clothes together at any temperature, because Procion MX dye is very permanent. If the clothing can't tolerate a hot-water wash, just wash it separately from other colors for a few months.

If the blouses are permanent press, the color might end up lighter than you expect, but dyeing should still work well. If they are stain-resistant, they can't be dyed. In almost all cases, the stitching at the seams is made of polyester and will stay white.

There is a small risk in dyeing purchased clothing that's not labeled PFD ("Prepared For Dyeing"). Sometimes, rarely, one part of the shirt may take dye differently from another part, due to having been cut from a different bolt of fabric, or to an accident with the invisible surface finishes that are used on fabrics. You're taking a risk when you dye anything, but it almost always works out.

(Please help support this web site. Thank you.)

All of the above is for dyeing a single solid color, which requires a lot of water and a lot of stirring. A much easier form of dyeing involves putting a blouse in a smaller container, scrunching it up first, and pouring the same type of dye and only a small amount of water over it, only enough to barely cover the fabric, then pouring over a little dissolved soda ash and leaving it to react. No stirring is required. This method is called low water immersion dyeing, and it creates a more interesting multi-shade or multi-color effect, though much subtler than tie-dyeing. For instructions, see How to Do Low Water Immersion Dyeing.

After you're done dyeing, there's a lot of unattached excess dye that has to be washed out. Wash first in cool water, then wash twice in very hot water, if the clothing can handle it. After this initial washing is completed, it's safe to wash different-colored clothes together at any temperature, because Procion MX dye is very permanent. If the clothing can't tolerate a hot-water wash, just wash it separately from other colors for a few months.

If the blouses are permanent press, the color might end up lighter than you expect, but dyeing should still work well. If they are stain-resistant, they can't be dyed. In almost all cases, the stitching at the seams is made of polyester and will stay white.

There is a small risk in dyeing purchased clothing that's not labeled PFD ("Prepared For Dyeing"). Sometimes, rarely, one part of the shirt may take dye differently from another part, due to having been cut from a different bolt of fabric, or to an accident with the invisible surface finishes that are used on fabrics. You're taking a risk when you dye anything, but it almost always works out.

(Please help support this web site. Thank you.)

Tuesday, June 26, 2012

How can I dye shirts by floating dye on the surface of water to get a marbled effect?

Name: Lynn

Country or region: Michigan, US

Message: Good morning, I found your site through google search, I have to say it's amazing. I'm trying to figure out how to dye shirts(cotton tank tops or wife-beaters) by floating the dye on the top of the water, to get a marble effect. I've tried every search I can think of and I'm getting nothing. Is there a name for that type of dying? Do you have any idea how to do it? I want it to be similar to the Easter egg kits you can get, the dye floats on the water and you put the egg in and it comes out marbled. Hope you can help, we are looking to do this for my daughter's baton team and I want it to look just right.

What you're looking for is, in fact, called marbling. You cannot do marbling with dye, because dye is water-soluble and just mixes with the layer below; instead, you use the right sort of fabric paint. The fabric paints are floated on the surface of a thick mixture of carageenan in water, then swirled around in the characteristic marbling patterns, after which you lay the fabric down flat on top of the layer of paint. Dharma Trading Company provides a good tutorial for marbling fabric, complete with links for ordering all of the materials.

Alternatively, a completely different form of dyeing, foam dyeing, gives effects rather similar to marbling, and is suitable even for use by beginners. Start by soaking 100% cotton or rayon in the same soda ash presoak that we used for tie-dyeing, one cup of soda ash per gallon, then line-dry the garments so that they still contain the soda ash, but no water. Then use the cheapest brand of shaving cream, mixing it with a strongly concentrated solution of Procion MX dyes in water. Spread the different colors of your dye/foam mixture out in a tray and manipulate them to make your design, then lay your soda-ash-treated fabric on top of the dye foam. I first learned of this technique from John Choma on the DyersLIST mailing list in 1997, but it has since become very popular. Again, Dharma Trading Company includes directions for foam dyeing with Procion MX dyes now, and they are easier to understand and follow than Choma's ever were.

With both of these techniques, practice is required for better results, so be sure to try some test pieces before you start your daughter's team's project.

(Please help support this web site. Thank you.)

(Please help support this web site. Thank you.)

Saturday, June 23, 2012

I need to know if I can use both food coloring and regular color dye for a cotton sheet just to make the color darker?

Name: Dawn

Country or region: United States

Message: I need to know if I can use both food coloring and regular color dye for a cotton sheet just to make the color darker???? Thank you for your time...

No. Do not use food coloring on cotton. It's nothing but a waste of time and food coloring, because food coloring will not stick to cotton. Food coloring serves as an acid dye, which means it works as a dye only on certain fibers. These fibers include wool and all animal hair (even human hair!), as well as silk and, surprisingly, the synthetic fiber nylon (but no other synthetic), but not cotton. Acid dyes simply do not stick to cotton, not for long at all.

Basically, any food coloring you apply to cotton is wasted, a waste of both food dye and effort, because it will bleed right out the first time you wash the cotton, leaving no more than a pale temporary stain. If you want a non-temporary cotton dye, then you must find a good fabric dye and use that.

Basically, any food coloring you apply to cotton is wasted, a waste of both food dye and effort, because it will bleed right out the first time you wash the cotton, leaving no more than a pale temporary stain. If you want a non-temporary cotton dye, then you must find a good fabric dye and use that.

Procion MX fiber reactive dye is the best fabric dye to choose. It is available in all colors, ranging from subtle earth-tones to incredibly brilliant neon hues. The only problem with Procion dyes is that you probably have to order them online. Procion MX dye is cheaper per pound of clothing, than all-purpose dyes, such as Rit; its colors are far more predictable and beautiful; and, perhaps most importantly, they are permanent, lasting at least twenty times longer before fading, something all-purpose dye is not very good at. Even the use of the Procion dyes is much easier, because they are set at room temperature by a household cleaning chemical often used in laundry detergent powder, known as washing soda or soda ash. Unlike all-purpose dyes such as Rit, Procion MX dye is used at room temperature, a huge convenience. Rit dyes work best when simmered to nearly boiling in an huge non-aluminum pot you can't even use again for cooking, once you've ruined it by cooking all-purpose dyes in it. You can use Rit dye in the washing machine, but the lower temperature results in paler colors that fade more quickly. Procion MX dyes produce permanent intense colors in the washing machine.

Even with all the many advantages of Procion dye over all-purpose dyes such as Rit, all-purpose dye is still a tremendously better choice than food coloring, for coloring or darkening a cotton sheet. All-purpose dye will fade and bleed and no longer look as fresh after several washes, but that is much, much better than the way food coloring fades out immediately! At least you get some use out of it before it fades.

If you want dark colors while using Rit dye, you should increase both the amount of dye and the amount of heat. Rit is a hot water dye and works best when simmered for an hour with your sheets or clothes in a very large pot of water and salt, stirring constantly. For a medium shade, you can use one-half to one box of Rit to dye half a pound of cotton sheeting; use more for darker colors, or less for pale colors. Since your sheets weigh more (dry) than 8 ounces, you have to use several boxes of dye, one to two boxes for every pound of fabric, in order to get a medium shade. Weigh yourself with and without all of the sheets you're dyeing, to get an idea of how many pounds the sheets weigh. For dyeing three pounds of sheets to a medium color, use 3 to 6 boxes of Rit dye. (Your local sewing or crafts store probably won't carry many of any single color in stock, so you may have to drive from store to store to buy enough; ordering easier-to-use, more economical, and more beautiful Procion dyes online is sounding better and better!)

For dark shades, you must double or triple the amount of dye you add, so, for example, three pounds of 100% cotton sheets will require not just 6, but 12 to 18 boxes of Rit dye. You can buy just one large jar of superior Procion dye for far less than the cost of thirty boxes of Rit, even including the cost of shipping.

Conclusion: save your food dye for coloring food, or dyeing wool yarn or silk scarves, or even your own hair. Rit dye is much better than food coloring, when you're dyeing cotton, but you'll probably need to invest in a large number of little boxes of dye, and, ideally, acquire a 3-or 4-gallon non-aluminum cooking pot for using hot-water dyes in. Procion MX dye is better, cheaper, and easier to use; it's only drawback is that you must order it online. Try ordering from Dharma Trading Company if you're on the west coast, Grateful Dyes in Colorado, or PRO Chemical & Dye on the east coast, or see my list of Sources for Dyeing Supplies Around the World.

(Please help support this web site. Thank you.)

Monday, June 18, 2012

Name: Geri

Country or region: Wisconsin

Message: I am tye dyeing with 200 kids at my campground. I don't see info in dyeing in big buckets for a non-toxic mix on cotton shirts. I need help. I'm in a time crunch!

Big buckets? Do you mean you will have the kids tie and then drop their shirts into buckets of a single color of dye, instead of doing the usual modern multi-color tie-dye?

First off, let me recommend strongly against all brands of all-purpose dye, including Rit dye, for tie-dyeing. It is not non-toxic (though fortunately the older formulations containing carcinogenic dyes were discontinued in the 1980s), it gives poor results for tie-dyeing, its colors run and bleed together, it lasts through few washings before fading, it's very expensive since each $3 packet of dye will dye only two shirts, and it requires scalding hot water, which is unsafe for children to work with.

The best choice for tie-dyeing with kids is a Procion MX tie-dyeing kit, which contains fiber reactive dyes. However, the kids must be capable of following directions so that they do not drink the dyes or intentionally apply them to their own skin or to other children. Some brands of kits that contain Procion MX dyes are labeled non-toxic, though most are not. To quote from an earlier blog entry on this site, from September 27, 2008:

"Procion MX type dyes are considered non-toxic when used properly, that is by people who are old enough and sensible enough not to put the dye in their mouths or squirt it on each other. However, the Jacquard Products tie-dye kit [like Dharma Trading Company's kit and ProChem's kit] does not carry an ACMI Non-toxic Seal on the label. The same ingredients are found in the Rainbow Rock tie-dye kit (produced by a different manufacturer), which does bear a nontoxic label with a reference to the ASTM D-4236. This does not guarantee that a product is completely non-toxic, but it does indicate that it is free of known acute or chronic health hazards other than those indicated on the label.

"You will need the MSDS pages if it is necessary to officially show how toxic or non-toxic the dyes are. This must be supplied by the manufacturer of your kit. [If] you are using the Jacquard Products kit, you can look at this link to the MSDS pages at Blick Art Materials [PDF]. Here is a link to the new MSDS clearly including the "nontoxic" seal [PDF] for the Rainbow Rock tie-dye kit, which contains the exact same ingredients. It is easier to read and also less alarming, but it's for the same product by a different manufacturer. MSDS pages are also provided by PRO Chemical & Dye and by Dharma Trading Company, which are the two most popular (and economical) sources of Procion MX dyes."

"You will need the MSDS pages if it is necessary to officially show how toxic or non-toxic the dyes are. This must be supplied by the manufacturer of your kit. [If] you are using the Jacquard Products kit, you can look at this link to the MSDS pages at Blick Art Materials [PDF]. Here is a link to the new MSDS clearly including the "nontoxic" seal [PDF] for the Rainbow Rock tie-dye kit, which contains the exact same ingredients. It is easier to read and also less alarming, but it's for the same product by a different manufacturer. MSDS pages are also provided by PRO Chemical & Dye and by Dharma Trading Company, which are the two most popular (and economical) sources of Procion MX dyes."

You can equally well apply Procion MX dyes by high-water-ratio immersion dyeing in large buckets, if you buy your Procion MX dye in jars from a dye supplier such as Dharma Trading Company instead of buying kits. This method is less popular because people love multi-colored tie-dyes, but it can be used to keep the kids completely away from the dye. The constant stirring required to get a smooth solid color in garment-dyeing is not needed when dropping tied garments into the bucket. For a 25-gallon trash can, dissolve 20 cups of salt in 20 gallons of water (salt is not needed for the squirt-bottle method of tie-dyeing), and add four ounces of Procion dye powder, having first mixed the dye powder carefully in a quart of water. After all of the shirts have been added to this bucket, add two and a half cups of soda ash (purchased with your dyes) which you have predissolved in water, and mix well. Leave the shirts for an hour or longer to react, stirring occasionally. Do not wait to add the shirts until after the soda ash has been added, because the dye will stay good for only a limited period of time after you add the soda ash, and is most effective in the first half hour after adding the soda ash.

The soda ash used to fix these tie-dye dyes is not non-toxic; it is a fairly mild alkali, the same one that is found in all laundry detergent powders, and can be irritating to the skin or eyes, so gloves should be worn to prevent contact. If soda ash is splashed onto the skin, it should be rinsed or wiped off, to prevent later redness and dryness of the skin. If the soda ash is not removed, then thorough washing afterwards with water, followed by the application of hand lotion, will help to sooth irritation.

You should have the kids tie their shirts with rubber bands when the shirts are still dry, or dampened only with plain water. Attach some sort of label. (Pinning on a label made of a piece of Tyvek envelope labeled with a Sharpie permanent marker works well; use stainless-steel or brass safety pins to attach the labels, instead of rustable pins. Any sewing store should have these safety pins.) Drop the shirts into a large plastic trash can half-filled with soda ash and water mixture (use one cup soda ash per gallon of water) to soak for fifteen minutes or so, then have an adult fish out the shirts and squeeze out extra moisture. After this point, the children should be wearing waterproof gloves. (Be sure to warn the parents not to send the kids in good clothes for this day of camp.) Each should place his or her shirt on the work surface (tables covered with plastic tablecloths work well, with plenty of paper towels or rags nearby to soak up excess), then squirt dye from bottles supplied by you onto their shirts. They should then pop their shirts into a plastic bag, take them home, allow the dye to react with the shirts overnight, then wash the shirts out the following day, doing one cool-water wash and then two or three hot-water washes to remove the excess unattached dye.

Procion dye is sold in the form of powder. Do not give dye powder to the children to mix up; instead, you or other adults should dissolve the dye in water (while wearing dust masks) and place it into the plastic squirt bottles that come with the kit. If the kit you use comes with the soda ash in a separate bag, then you can mis the dye a day or two in advance of the day the kids will be using them. If, on the other hand, you buy a kit that has the soda ash already mixed in with the dye powder, you must mix the dye in with the water only at the last minute, immediately before use. This seems inconvenient to me when working with children, so I would much rather get the sort of kit that calls for a separate soda-ash presoak, such as the kits made by Jacquard Products or the kits you can order from Dharma Trading Company or PRO Chemical & Dye.

Be sure that all of the items you try to dye are 100% cotton, or nearly so, and then none are marketed as being stain-resistant (and therefore dye-resistant). Garments that are 50% cotton/50% polyester will dye in pastel colors. 100% synthetic garments will not take the dye, except for rayon, which dyes very much like cotton.

An alternative to dye which gives markedly poorer tie-dyeing results is to substitute a thin fabric paint, such as Jacquard's Dye-Na-Flow or Dharma Trading Company's Dharma Pigment "Dyes", for the dye. Many fabric paints are labeled "non-toxic" though in fact their toxicity is probably quite similar to that of the Procion dyes, if anyone is foolish enough to eat them. Fabric paint does not require soda ash to set it, but it does require heat-setting. This can be done by pressing every shirt (after it has dried) with a hot iron so that each part of it is exposed to high heat for a minute or so, depending on the manufacturer's instructions, or by putting the (already dry) shirts into a commercial clothes dryer on "hot" for half an hour. Home clothes dryers tend not to produce high enough temperatures to set the fabric paint permanently.

I recommend you order two "Tie-Dye Big Group Kits" from Dharma Trading Company or two "Tie Dye Party Packs for 100 people" from PRO Chemical & Dye. They do have expedited shipping if necessary. Buy lots of extra pairs of size extra-small waterproof gloves, either the reusable dishwashing type, or the disposable latex or nitrile or vinyl type. Blick Art Materials carries latex gloves in kids' size for ages 6 and up. If all you can find are size small, you might want to make sure you have rubber bands to hold them onto the wrists of the smaller kids.

(Please help support this web site. Thank you.)

(Please help support this web site. Thank you.)

Saturday, June 16, 2012

Name: Christina

Country or region: Pennsylvania, USA

Message: Is it possible to dye a silk velvet burnout dress with a completely sewn-in rayon liner? It is currently a cream color (and marked dry clean only). I was hoping to get it to a fairly rich brown.

You can't dye anything if you can't wash it. See my page, "Can I dye clothing that is labeled 'dry clean only'?". If you wash it, the rayon lining might shrink more than the silk/rayon velvet outer layer; if the lining shrinks, the shape of the dress will be ruined, unless you pull out the lining and sew in a new one (or wear the dress with a slip under it, after removing the lining).

If you wash the dress and it's still okay afterwards, then you certainly can dye it. At this point things get interesting. Silk devoré is typically made with a silk backing material and rayon plush. The thicker areas you see are made of rayon, while the thin burned-out areas are silk. Silk and rayon may take the same dye differently, so what is brown on the rayon might turn out to be a more reddish or greenish color on the silk. The color contrast is unpredictable, but usually the results are lovely.

I recommend, if your dress survives prewashing, that you choose a brown Procion MX fiber reactive dye. Procion MX dyes work very well on both rayon and silk. You can set the Procion dye with soda ash. You can try for a solid color by doing this in the washing machine (see "How can I dye clothing or fabric in the washing machine?"), or you can lay it flat (some people use a plastic tarp underneath, others a layer of old towels which will also get dyed) and use tie-dyeing dyes to squirt different colors or shades of dye onto different areas of the dress.

Another type of dye, acid dye, would color the silk backing while only staining the rayon plush slightly. I don't think you'll want to use acid dyes alone on silk/rayon burnout fabric. You could use acid dyes as a second step if you happen to dislike the color that Procion MX brown dye produces on your silk backing.

In a very different approach, you could choose to dye the rayon and silk in contrasting colors by buying a kit of Alter Ego brand dyes. The main drawback to this option is expense: each small jar of Alter Ego dye costs over $20. Also, the dyes must be applied in a non-aluminum cooking pot that is large enough for the dress to move in freely when stirred; do you already have a large dyeing pot? If not, this would represent a major investment, since the pot must be made of stainless steel or enamel, and should not be reused later for food.

Finally, I must mention all-purpose dye. All-purpose dye has led to more disappointments in dyeing than other types of dye, and yet one great advantage is that it's supposed to produce more-or-less the same color on rayon as it does on silk. It would not be a bad choice for your dress (assuming, as before, that you first succeed in washing the dress without ruining it). You should add both salt (for the rayon) and vinegar (for the silk) to your dyeing pot if you choose to use all-purpose dye. Again, as for acid dyes and Alter Ego dyes, you can't do this at the room temperature that works fine for Procion MX dyes. All-purpose dye can be used in very hot tap water, but produces better results if heated to a simmer with the garment in a large non-aluminum dyeing pot, three or four gallons in size. All-purpose dye tends to bleed badly in the wash, but that won't be a problem if you revert to only dry-cleaning the dress in the future.

No matter what dye you use, if you want the dress to end up in solid colors rather than splotches of lighter and darker brown, you will need to stir constantly during the dyeing process, whether you're using Procion MX dye in a bucket, or Alter Ego dyes, acid dyes, or all-purpose dyes in a cooking pot, or all-purpose dyes in a bucket with the hottest tap water you can achieve. If you do your dyeing in a washing machine, the agitator takes care of the stirring problem (though it may tear delicate fabrics), but you must reset the timer on the washer several times before the water drains, so that you get at least half an hour of dyeing time, or preferably a full hour. Carefully follow the instructions for the type of dye that you choose to use.

(Please help support this web site. Thank you.)

Friday, June 15, 2012

What is the best method and dye to dyeing crochet cotton threads to get really vibrant colors, both solid and rainbow?

Name: Daniella

—ADVERTISEMENTS—

Linda Johansen's book

Fabric Dyer's Dictionary

shows how to mix a small number of Procion dyes to obtain a large number of different solid colors

Country or region: USA

Message: Hi, I got your site from Marilee Rockley. I am most interested in dyeing my crochet cotton threads myself to get really vibrant colors, solid and rainbow. What is the best method and dye for that project? Would the thread have to be unwound and skeined to dye it? Heat treated? I have never dyed anything really, and would love to be educated. Thank you for your time to my questions.

The best dyes for cotton are the fiber reactive dyes. They are easier to apply than heat-set dyes, their colors are more vibrant and predictable, you can mix them to obtain any color, and they last far longer than other types of dye. The most popular and the least expensive of the fiber reactive dyes are the Procion MX dyes.

Only the very best crafts stores carry these dyes, so you will probably want to order them online. If you're on the east coast, order them from PRO Chemical & Dye; on the west coast, from Dharma Trading Company; or see any of the many dye suppliers listed on my page, "Sources for Dyeing Supplies Around the World". You can also start with a good tie-dyeing kit, which can be found in most hobby or sewing stores. I recommend the Jacquard Products tie-dye kit. The dyes in the kit work well for rainbow-dyeing any form of cotton.

The thread you start with will affect your final results. A plain white will give the most versatility in color choices. A "natural" color thread, which is slightly yellowish, will alter the color of the dye you apply to it, making blues greener and reds more orangish. Mercerized cotton, as well as rayon thread, will produce the brightest colors of all, as the result of the processing of the cellulose fiber, which cleans off fuzzy fragments of fiber from the surface of the thread that will otherwise make colors appear lighter.

As a general rule, you do need to unroll and skein your thread before dyeing it, since it's likely to be sold wound so tightly that dye applied to the outside of the ball will not reach the inside. You can start by winding it around a piece of cardboard or the top of a hardback chair. Use a synthetic yarn or string, such as acrylic or nylon, to loosely tie the thread in many places, to keep it from tangling during dyeing.

If you're using Procion MX dyes, you don't have to worry about heat-setting, since this dye is set at room temperature with the use of soda ash or washing soda. This is a common household chemical you've probably used many times already, since it's a major ingredient in laundry detergent powder. Since you don't have to heat your thread to set the dye, there's no need to invest in a good dyeing pot. The inside of the lid of a plastic storage bin makes a handy surface for working on.

Procion dye can be applied in many different ways, depending on what color effects you want. You can apply it in a bucket in a large volume of water with salt, in order to obtain plain solid colors (be careful not to tangle the thread while stirring). You can mix up different colors of dye and paint or drip them on to different parts of your thread, for multicolored or rainbow effects. You can tie your bindings tightly to resist the dyes for striking contrast in color and intensity. You can add alginate to your dyes to thicken them if you want them to spread less on the thread, or you can use unthickened water to dissolve them in order to let the dye mix and blend more easily on the thread.

There are a hundred different pre-mixed colors of Procion dye available from the major dye suppliers. You can enjoy picking out all of your favorites, or you can choose the basic mixing primary colors of magenta, cyan, and yellow, as well as orange, navy, and black, and mix your own colors. See "What colors should I buy to start out with?", "Which Procion MX colors are pure, and which mixtures?", and "How can I mix Procion MX dyes to get specific colors?".

For recipes in how to apply dyes, once you've skeined your thread, see the basic direct dye application recipe in "How to Hand Dye", "How to Tie Dye", and "How to Do Low Water Immersion Dyeing". Also, check with your dye supplier to see if they have recipes available online. Note that not all of the dye will attach to the fiber, so you need to add enough dye to make it look too dark at first, so it will be the right color after washing out the excess.

After you've dyed your threads (most recipes call for leaving the dye on them overnight, but solid color dyeing takes only an hour), you will need to wash out the unattached excess dye. If you don't remove this unattached dye, it will run or rub onto other things. Rinse first in cool water, to remove the soda ash and any salt, then wash it with hot water, the hotter the better. Unlike other dyes, the properly attached fiber reactive dye will not wash out even in boiling water. To be sure you've removed all the loose dye, use the hot press test, dampening the fabric and placing it between two white cotton cloths before pressing it dry with a hot iron; if any color transfer occurs to the white cloth, repeat the hot-water wash.

A good place to discuss your work is the Dye Forum; you can join it for free. It doesn't send notifications when replies are posted, so you have to check back later to see if there are any. Don't forget, as part of the initial registration process, to send me a personal message about your interests in reply to the automatic email you receive after registering; this allows me to distinguish a real application from the dozens of bogus applications the forum gets from robospammers every day.

(Please help support this web site. Thank you.)

(Please help support this web site. Thank you.)

Thursday, June 14, 2012

Does ProChem have an equivalent to Dharma's Fire Red or Avocado Procion dyes?

Name: Erin

—ADVERTISEMENTS—

Linda Johansen's book

Fabric Dyer's Dictionary

shows how to mix a small number of Procion dyes to obtain a large number of different solid colors

Country or region: USA

Message: I looked to see if you have a match for Dharma FIRE RED and AVOCADO on Pro Chem and Dye. I live on the east coast and shipping is killing me. I am in love with those colors though. I need to buy asap to teach a class. I have heard good things about Chinese red which has a mate with Pro chem...but I really love the FIRE RED and i am scared it will be a big change.

I am also having a hell of a time with black. I do a penguin design that is mostly black. I use squirt bottles and wonder...I have never done a vat dye...I also worry the stuff I think recommended on here has to be warm..but I keep mine refrigerated. So...

Dharma's Fire Red and Avocado Procion MX dyes are both mixed in-house by Dharma, sorry, which is why you didn't see them on my charts on "Which Procion MX colors are pure, and which mixtures?". My best advice is to try all the ProChem colors whose color chips in the catalog look closest; compare their printed color chart to the one in the Dharma printed catalog, if you can, instead of just comparing it on a computer monitor. None of the in-house color mixtures will be an exact match, but maybe some will be just as good. ProChem's Grass Green looks pretty close, but there's no telling for sure until you test it on fabric. Their avocado looks a bit yellower than Dharma's, in the color chip. The reds are harder to compare from a color chip, at least for me.

Vat dyes are a different type of dye than reactive dye. You probably don't want to use them now.

Refrigerating dye would not be a problem for the warmer-water dye. All reactive dyes become unreactive at refrigerator temperature, which is why you refrigerate to make the dyes last longer. They all have to be warmed up for the dye reaction to occur; for Procion dyes, putting the refrigerated dyes on room-temperaqture cotton, with room-temperature soda ash, is enough. For Remazol dyes it's best to let the dyes "batch" on the cotton at a warmer temperature, either in hot weather outside, or by microwaving a shirt for a minute while it's still wet with dye, or by putting them inside a black plastic garbage bag in the sun or inside a hot car or something. No need for the warmth until after the dye and soda ash are on the fabric.

Reactive Black 5, which is sold by ProChem as their Liquid Reactive Remazol black, is a great dye but so are the various Procion MX black mixtures. The advantage of the Liquid Reactive Remazol black is that it won't separate out at the edges no matter what, since it's a single-color dye instead of a mixture. Dharma's New Black, or black MX-CWNA, was identical to the ProChem Procion #608 black until Dharma had to change the formula during a shortage of one of its constituent colors, so the 608 Black will be familiar to you if you've been using Dharma dyes for a few years. (This Dye Forum post includes a picture of two Dharma blacks and two ProChem blacks (from The Fabric Dyer's Dictionary.) I just used some of ProChem's black 609 in tie-dyeing and did not like it as much as their 608 black. The 609 black is a bit greener. No matter which black you use, use twice as much dye powder as you would for another color, if not more. Disappointing blacks are usually caused by not using a large enough quantity of dye powder.

(Please help support this web site. Thank you.)

(Please help support this web site. Thank you.)

Wednesday, June 13, 2012

Please let me know whether Drimarine K dyes are monofunctional or bifunctional.

Name: Mrs Tanveer

—ADVERTISEMENTS—

Books about the chemistry of dyeingJohn Shore's

Cellulosies Dyeing

Useful information about the chemistry of reactive dyes, and other dye types used for cotton and other plant fibers

Victor B. Ivanov's

Reactive Dyes in Biology and Medicine

Explains use of reactive dyes for staining proteins or carbohydrates

Heinrich Zollinger

Color Chemistry: Synthesis, Properties, and Applications of Organic Dyes and Pigments

Country or region: Pakistan

Message: Please let me know whether Drimarine K dyes are monofunctional or bifunctional.

Drimarene K dyes are monofunctional dyes, with one chlorodifluoropyrimidine reactive system per dye molecule. See the chart from John Shore's book Cellulosics Dyeing at the bottom right of my page about fiber reactive dyes.

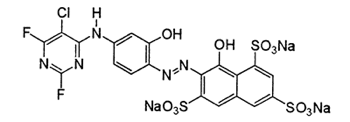

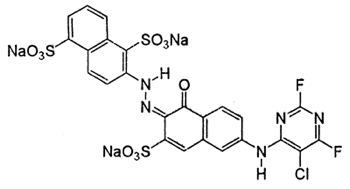

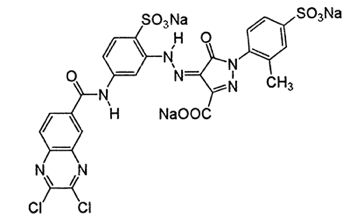

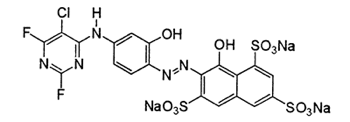

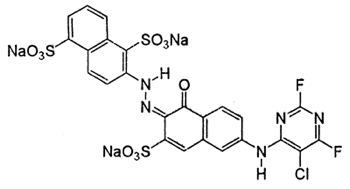

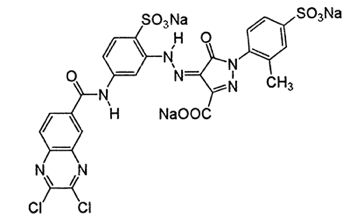

Here are some examples of molecular structures of Driamarene K dyes, starting with reactive violet 33:

[image from http://www.worlddyevariety.com/reactive-dyes/reactive-violet-33.html#more-4468]

and another, reactive orange 64:

[image from http://www.worlddyevariety.com/tag/reactive-orange-e3ga]

Reactive yellow 25 is listed as a Drimarene K dye, but it lacks the fluorine atoms of the other two:

[image from http://www.worlddyevariety.com/reactive-dyes/reactive-yellow-25.html]

Each of these examples is obviously monofunctional. There's only one reactive section to the molecule, which is the end with chlorine and/or fluorine atoms; the rest of the molecule is the chromophore, which creates the color, and the connection in between the two parts.

(Please help support this web site. Thank you.)

Friday, June 08, 2012

Can you give me some advice on how to dye both fabrics in a polyester lace dress lined with cotton?

Name: Deanna

—ADVERTISEMENTS—

Dye polyester and poly/cotton blends

Enameled canning pots make good dyeing kettles

Columbian Home 33-Quart Jar Canner and Rack

Holly Brackmann's book

The Surface Designer's Handbook

includes directions for dyeing with disperse dyes

Country or region: USA

Message: I have a dress (yes I know, I read your post about dying formal dresses), but this is not dry clean only. It is a lace made of polyester over a 97% cotton fabric. The fabric is visible through the polyester lace. I am very invested in dying this dress, can you give me some advice on how to make a uniform dye of the polyester and the cotton? It is hot pink now, I would prefer literally any other color. I though navy blue or black might cover nicely. Thank you for your help.

The cotton will need to be dyed with a different dye than the polyester. Neither fiber will take a dye that works on the other. A good dark black on each fabric should match well enough to look good, though. Navy blue and black are both good color choices for covering hot pink. Other options would be orange, red, maroon, purple, or dark brown.

Since cotton's easy to dye, think about the polyester dyeing first. The only kind of dye that will work on polyester is disperse dye. Dyeing polyester with disperse dye requires boiling it for an extended period of time; an hour would be good. Unlike cotton, polyester cannot be dyed in the washing machine. (I hope that boiling will not cause the cotton lining of your dress to shrink.)

You'll need to find a very large cooking pot for dyeing in, one you will not plan to ever reuse for food. If you want the polyester to be dyed the same color all over, your pot should be big enough that the dress moves in it freely and easily in the water when you stir it, with extra room at the top so that you don't splash the dye during your hour of constant stirring. If your pot is too small, parts of the polyester will dye lighter, and part darker, giving a sort of tie-dye effect, so the size of your pot really matters. The pot will be your biggest expense in this project, but it will be useful for other dyeing projects in the future. You should choose a pot that's made of either stainless steel or enamel, not aluminum; the least expensive alternative would be an enamel canning pot. You can buy a thirty-three quart (eight gallon) enamel canning pot for less than fifty dollars from Amazon, or you might be able to find it locally; in addition to kitchenware stores, sometimes hardware stores have them. (See "Why does everyone say never use an aluminium pot when dyeing?".) You'll also need a long-handled spoon to use to stir your dress as it dyes.

Disperse dye can be ordered in the US from several different suppliers. The easiest to find is Jacquard iDye Poly, which comes in eight different colors, including black. You can order it from any retailer of Jacquard Products, including Dharma Trading Company. Other good US sources for disperse dye include PRO Chemical & Dye in Massachusetts, with twelve different colors, and Aljo Mfg in New York, with twenty-two different colors of polyester dyes. Examine the recipe given by your dye supplier to see what other ingredients will be required.

For dyeing polyester a dark color, it's not enough to have disperse dye. You will also need a dye carrier chemical. This chemical is included in the Jacquard iDye Poly packet, and is sold separately as "PRO Dye Carrier NSC" by ProChem and as "Hi-Conc Developer" by Aljo. Without one of these dye carrier chemicals, the dye will not be able to reach its full color intensity. Unfortunately, this chemical smells horrible. Even if you open every window and door in your house, and have a fan on high in the window forcing good ventilation, the smell in the house can be quite unpleasant. I have not heard any report of anyone's becoming ill in any way from exposure to the carrier chemicals, but the safety data on the MSDS pages indicates that it's probably not a good idea to breathe much of any of them. Ideally you should either do your boiling outside, if you have a stove burner of some sort that you can use outside (I have one I obtained just for this purpose), or wear a cartridge respirator inside and ban everyone else (who's not also wearing a respirator) from your house until an hour or so after you have finished dyeing your polyester, so that you have a chance to air the house out. Note that a dust mask will provide no protection; you should use a cartridge respirator whose label indicates protection against organic vapors.

Compared to dyeing polyester, dyeing cotton is very easy. The easiest alternative for you would be to follow Jacquard Products' suggestion of adding iDye, which is a direct dye for cotton, to the same dyebath as your polyester dye, at the same time. Another alternative would be to use a fiber reactive dye such as Procion MX dye, since it lasts longer on clothing before fading than any direct dye. Procion MX dye is very easy to apply in a plastic bucket or the washing machine, since it doesn't require boiling; however, you can't apply it at the same time as disperse dye. There's a great appeal to the one-step convenience of applying iDye and iDye Poly at the same time.

Be sure to use enough dye, when dyeing a dark color. Weigh your dress, while it's dry, to see how much it weighs (if your kitchen scale and bathroom scale won't measure something of that weight, try a post office scale or a scale in the produce section of a grocery store). Check the instructions for the dye you choose and multiply it by the number of pounds of dry fabric you have, if necessary. Using too little dye for the weight of your fabric will result in a lighter color than you expect.

(Please help support this web site. Thank you.)

(Please help support this web site. Thank you.)

Wednesday, June 06, 2012

Can I dye shorts that are 85% nylon and 15% elastane with a polyester lining?

Name: Jolene

Country or region: Canada

Message: I have shorts that are 85% nylon and 15% elastane with a polyester lining. I want to tie dye them but I'm not sure it will work or what die to use. Do you have any suggestions?

It's likely that you won't be able to use dye on these shorts at all, since nylon requires heat in order to be dyed, but elastane or spandex is heat-sensitive. Unfortunately, you can't dye nylon with the same cool-water Procion fiber reactive dyes we use for cotton. Check the garment care information label sewn into your shorts. If the shorts cannot survive very hot tap water, but instead must be washed only in cool water of 105°F or below (40°C), then you won't be able to use a true dye to tie-dye them.

For tie-dyeing nylon/elastane, I think it would be better for you to use fabric paints, instead of dye. Most fabric paints require heat-setting, with dry heat from an iron or a hot commercial clothes dryer, but some do not. An alternative to heat-setting that works fine is to instead add an acrylic catalyst such as Jacquard Products' AirFix to the paint immediately before using it. You cannot obtain as perfectly smooth a solid color with fabric paints as with a true dye, but you can get a pretty good tie-dye effect. You'll want to use a thin fabric paint, such as Jacquard's Dye-Na-Flow or Dharma's Pigment Dyes fabric paint.

Warning: not all nylons can be dyed or painted with fabric paints. An invisible surface finish on the nylon can interfere with the ability of fabric paint or dye to stick to the nylon. You can't tell whether your nylon has this sort of fabric finish until you try it, so be sure to test your fabric paint on an inconspicuous inner seam margin before coloring the entire garment.

If your shorts can survive hot water, then, unless the nylon has a surface coating that will repel dye, you have the option of dyeing them with acid dyes, following a good recipe for direct dye application (painting the dye on). After applying the acid dye and letting it dry, you will need a large cooking pot to steam the shorts in; see ProChem's instructions for direct application of acid dyes to wool and silk for the technique. For tie-dyeing nylon with a single color, you can tie the garment and drop it into a pot of hot acid dye, instead of steaming afterwards. Nylon is best dyed at 185°F, but elastane should never be heated above 140°F (60°C) at the very maximum, so you have to compromise.

There are many different acid dyes available. High-quality acid dyes can be ordered online; good sources in Canada include G&S Dye in Toronto, and Maiwa Handprints in Vancouver. A particularly good choice for nylon would be the dyes Maiwa still sells under the name of Ciba Washfast Acid dyes, though Ciba no longer makes them; they're the same as ProChem's Washfast Acid Dyes.

You won't be able to dye the polyester lining, because of the elastane. Polyester can't be dyed except under high-heat conditions, at or above boiling temperature, which will ruin the elastane. Elastane is heat-sensitive, and will lose its shape if subjected to the high heat polyester requires for dyeing. If you use dye, accept that the polyester lining will stay white, or whatever color you're starting with. Some fabric paints will work on polyester, though.

(Please help support this web site. Thank you.)

Monday, June 04, 2012

What kind of dye goes on clear and develops under sunlight?

Name: Cindy

—ADVERTISEMENT—

Artistic Photographic Processes

Artistic Photographic Processes

by Suda House Country or region: Colo. USA

Message: Hi! In the 70's and 80's I used a fantastic fabric dye. I could free paint with this dye. It went on clear and had a slight thick consistency. I would set it out in the sun, or under a sun lamp, and the paint would transform into quite vibrant colors. I cannot remember the name but do know they were based out of Oakland (maybe San Francisco) Calif. Can you help me??? Thanks Cindy!

Although most sun-painting is done with fabric paint, rather than dye, I believe what you're looking for is Inkodye, a true dye that is set by sunlight.

Inkodye contains prereduced vat dyes; like indigo, the most popular of vat dyes, they are soluble in water only when reduced, and become stuck inside fibers once they are oxidized. You can't see their final color until it is developed, so it can be a bit of a challenge to get the colors mixed the way you want them. The neat thing about Inkodyes is that, after exposing the fabric to light, you can wash the fabric to remove the dye wherever it was protected from light, leaving an image. You can put objects on top of the fabric during your light exposure, or use printed transparencies or photographic negatives, as long as the clear parts allow ultraviolet light to pass. (Don't use glass, because it blocks too much of the UV.)

You can buy Inkodyes through Dharma Trading Company, in fourteen different colors, or you can buy a few of the colors (blue, orange, and red) directly from the manufacturer's web site. Their biggest drawback is that they are not inexpensive! For the most intense colors, you should use the dye undiluted; dilute only for paler colors, using water or Inkodye Extender. A small 4-ounce bottle costs $11.50 from Dharma, or $12 from the manufacturer; a pint (473 ml) costs $32, while a gallon costs $175.

I recommend the book "Artistic Photographic Processes", by Suda House, because she gives good step-by-step instructions for using Inkodye. There are also instructions on the manufacturer's website, but they lack some of the useful information, including differences in the speed of reaction for the different colors. For more information, see my page, "How to Dye and Paint Fabric with Light". Also see my earlier blog post, from February 11, 2011, "Problems in washing out Inkodye light-activated dye".

(Please help support this web site. Thank you.)

Sunday, June 03, 2012

How can I lighten dark blue shirts to light blue, without damaging the yellow iron-on logos

Name: Patty

Country or region: USA

Message: I have some dark blue tee shirts that I would like to lighten to a light blue but am unsure what product to use to do this. They are work shirts so I don't want to screw them up! They are 100% ultra cotton and there is a bright yellow logo on the front that appears to be iron-on that I also do not want to damage. Thank you for your time.

The trouble with removing dye is that the results are unpredictable, unless you dyed the shirt yourself and know exactly what dye was used. Some dyes will lighten in bleach or color remover, but some will not change color at all no matter what you do, and some will change to weird colors. It's common for a dark blue color to change to a light brown or weird dull orange, instead of white or light blue.

I think you'll want to avoid using household bleach, which is the hypochlorite-based stuff called chlorine bleach. There's a good chance it might damage the synthetic-material iron-on logo on the front of your shirts. Hypochlorite destroys nylon, and it tends to make polyester turn an ugly dull yellow that cannot be removed. The material in the iron-on logo might be undamaged by hypochlorite, but there's certainly a risk, since you don't know what it's made of.

That leaves sulfur-based color removers, such as Rit Color Remover, iDye Color Remover, and Thiox. (See my page, "What chemicals can be used to remove dye?".) There are several different chemicals you can use to remove color, but they're all based on producing sulfur dioxide when heated, and all give similar results to one another, different from the results of chlorine bleach. They are safer for a synthetic fabric than chlorine bleach. They all require heat; heating them on the stovetop works best, but it's so much easier to do it in the washing machine, with the hottest tap water available, that I always try that first. It often works, but not always.

The sulfur-based color removers are certainly not more toxic than chlorine bleach, probably less so, but they can be a real problem for people with asthma, so it's best to use them with excellent ventilation and/or a cartridge-type face respirator mask with acid gas cartridges. I don't worry about a mask when I use Rit Color Remover in the washing machine, because I don't stay in the room, and there is a window in the room where my washing machine is. I have not noticed any fumes. Be careful if you have asthma, though, and avoid any fumes in any case.

After you try Rit Color Remover in the washing machine (it'll probably require two or three boxes), you'll see whether it worked well enough. Maybe your dark blue will turn to a lighter blue, maybe it will turn an icky yellow, or maybe it won't change at all. If the shirts are not light enough, you can repeat the Rit Color Remover on the stovetop while wearing a respirator (not a dust mask!), or you can wash it out and try bleach, depending on how much of a risk you are willing to take. If they lighten too far, all the way to white, then you can consider yourself lucky, and then use a light blue Procion MX dye to color the shirts a light blue. Other types of dye will work, too, but all-purpose dyes such as Rit dye give inferior results.

If the yellow in your logo disappears when you use the color remover, which is likely, then you can use a yellow fabric marker to restore the color. If you use dye to color the shirts light blue, the logo may or may not take the blue dye, depending on what fiber it's made from, which is very hard to tell in advance. Polyester won't take any normal dye, but nylon will be colored by Rit. Procion MX dye will leave both polyester and nylon uncolored, but will color rayon. It is possible to use a resist to protect the logo while dyeing, but more information about that belongs in another question.

(Please help support this web site. Thank you.)

(Please help support this web site. Thank you.)