« 2007 December | Main | 2007 October »

Friday, November 30, 2007

any resource ideas for plain white canvas Keds sneakers (blanks for painting, so hopefully cheaper than keds)

Thursday, November 29, 2007

I have two all-white Chicago Cubs baseball caps that I'd like to dye a navy blue

Wednesday, November 28, 2007

planning to dye a sweatshirt that has a silkscreened design. will the dyeing process cause any shrinkage in this kind of garment?

Tuesday, November 27, 2007

How can I dye blue overalls to make them coral?

Monday, November 26, 2007

will the cold prevent the dyes working?

Sunday, November 25, 2007

My tub is now a nice shade of blue and scrubbing it with Ajax is NOT helping. Any ideas on how I can get it off

Saturday, November 24, 2007

I received a bleach stain on my beige cotton sweater. I would like to dye the entire sweater. Can this be done?

Friday, November 23, 2007

toxicity and environmental damage associated with logwood and other natural dyes

Thursday, November 22, 2007

backstaining of dye in batik, and unwanted pale colors in batik

Wednesday, November 21, 2007

the chemical, biological and physical processes and properties that generate the colours in clothing

Tuesday, November 20, 2007

Can I save soda ash mixtures for other tie dying batches in the future? If so, how long can I save it for, and in what conditions?

Monday, November 19, 2007

I have about 10m of natural wool to dye black, I bought a dye and tried a small off cut it turned out brown. So, to dye a natural wool, cream in colour, black, where did I go wrong and, more importantly, what do you suggest?

Sunday, November 18, 2007

dyeing a fishing vest so that it will not scare the fish

Saturday, November 17, 2007

I want to make a rainbow swirl tie dye with black "stripes" streaming out from the center. How do I get the stripes?

Friday, November 16, 2007

My daughter painted a banner on a sheet with crayola washable paint. I would like to make it into a quilt backing/blanket. Is there any way to set the paint and make this blanket washable?

Thursday, November 15, 2007

Dyeing bamboo sheets with Procion Mx dyes: is bamboo fabric sturdy enough to use soda ash on?

Wednesday, November 14, 2007

I have a light blue cotton shirt that doesn't come in black that I found on clearance. Now I want to make the shirt a medium gray color, don't care how even the color is, just don't want it baby blue colored.

Tuesday, November 13, 2007

I would need some azo dye structure of scarlet red, navilene brown, brilliant violet, remazol navy blue, remazol black, would you send through the mail

a science fair project on artificial dyes versus natural dyes

Monday, November 12, 2007

I am trying to find a dye house to dye large quantities of baby onesies for wholesale. Do you have any resources...

Sunday, November 11, 2007

Do you make scrub sets? I have been going crazy trying to find someone that does sets and not just tops.

Saturday, November 10, 2007

Will I have problems if I try to mix all purpose dye with fiber reactive dye to make a specific color? I was unable to find Rit Kelly Green color, so I bought some green Dylon Permanent Fabric Dye.

Friday, November 09, 2007

types of dye to use for dyeing Cordura nylon motorcycle clothing

Thursday, November 08, 2007

how can we set the dye in the bingo daubers we used to color our nylon cords for making rosaries?

Wednesday, November 07, 2007

I used a clothes dye but I can't get the dye off my hands wondered how I would get it off help

Tuesday, November 06, 2007

I bought some fabric dye from Dharma Trading company and I lost the directions. I want to dye a pair of jeans and I am very nervous.

Monday, November 05, 2007

dyeing a vintage silk kimono a fluorescent color: how does the lightfastness of these dyes compare?

Sunday, November 04, 2007

I have a dark purple 100% Acetate dress. Can it be dyed black? If so, how?

Saturday, November 03, 2007

lots of questions before tie-dyeing: alginate, IPA, urea chemical water, how much dye, how long to microwave

Friday, November 02, 2007

boysenberry or violet MX-BR

Boysenberry is listed among PRO Chemical & Dye's Procion MX dyes as "PRO MX Boysenberry 802 Violet MX-BR".

The code "Violet MX-BR" appears to be a made-up MX code, possibly from Standard Dyes which makes a habit of using incorrect MX codes (witness Standard's renaming of reactive violet 14 from violet MX-2R, which describes its color nicely, to the totally bogus violet MX-G). ProChem told me, when I asked some time ago, that they did not know what its Colour Index number was, and that they would ask their supplier, but they never got back to me. They said that it is definitely a single-hue unmixed dye, which agrees with my observations.

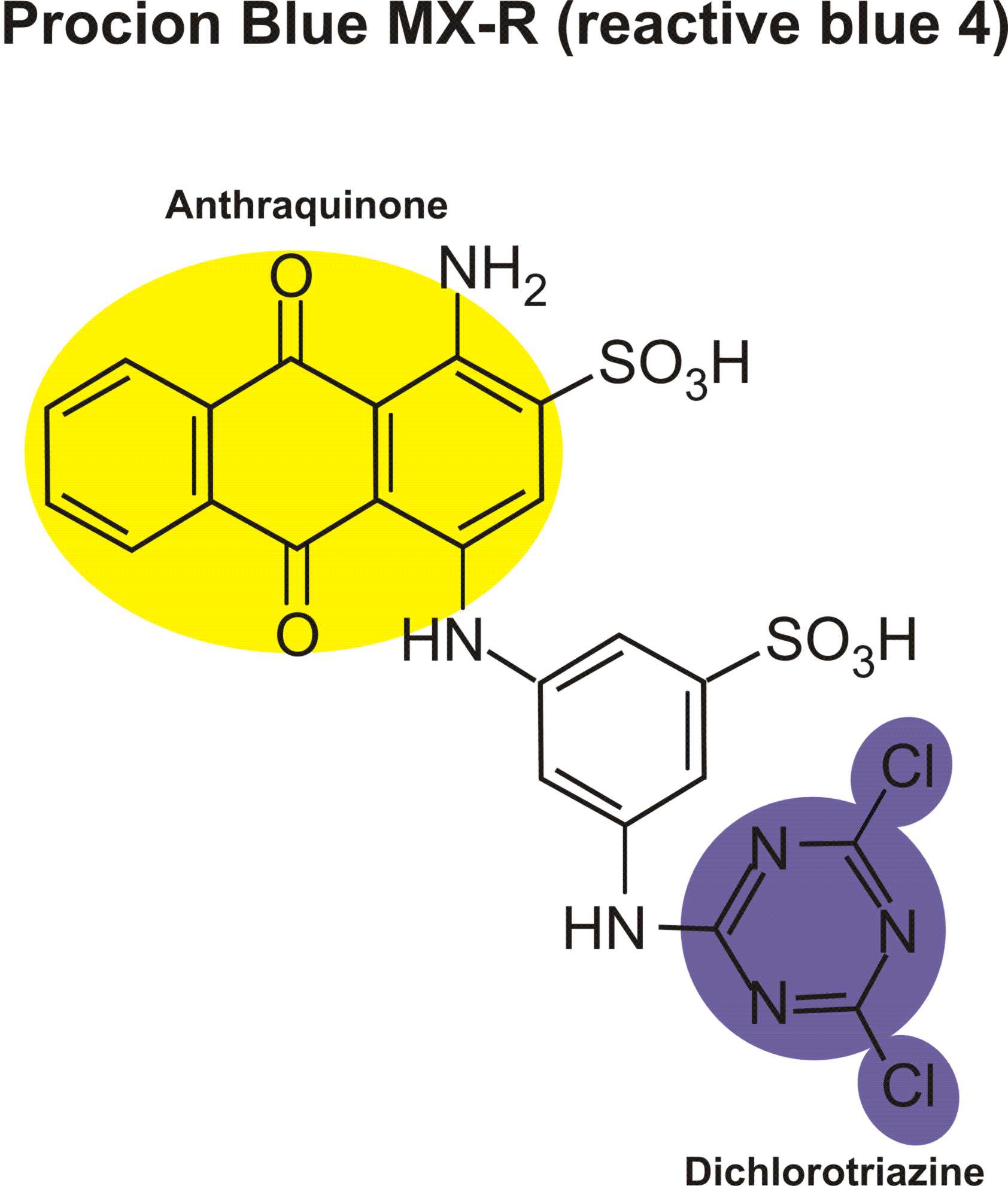

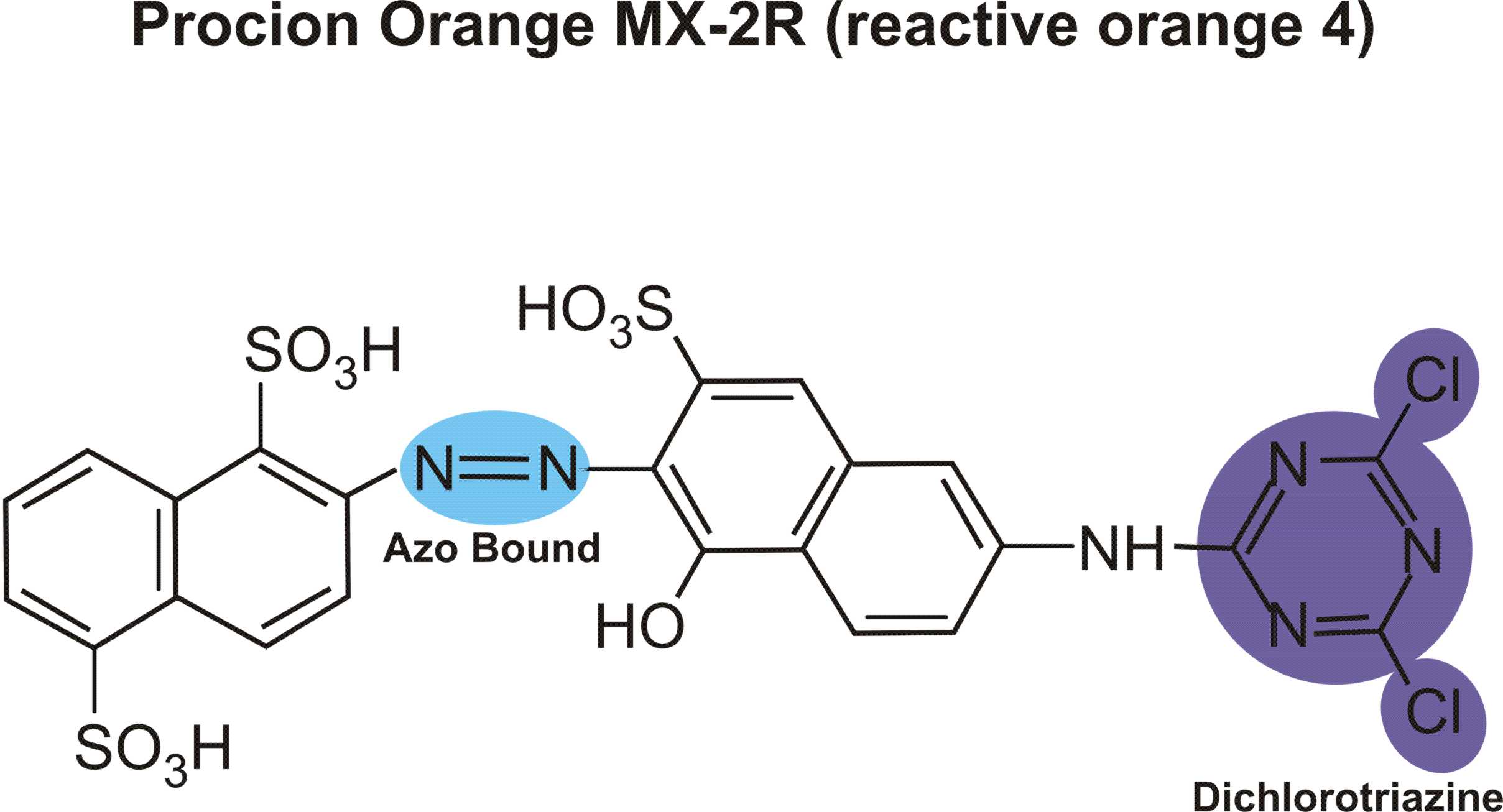

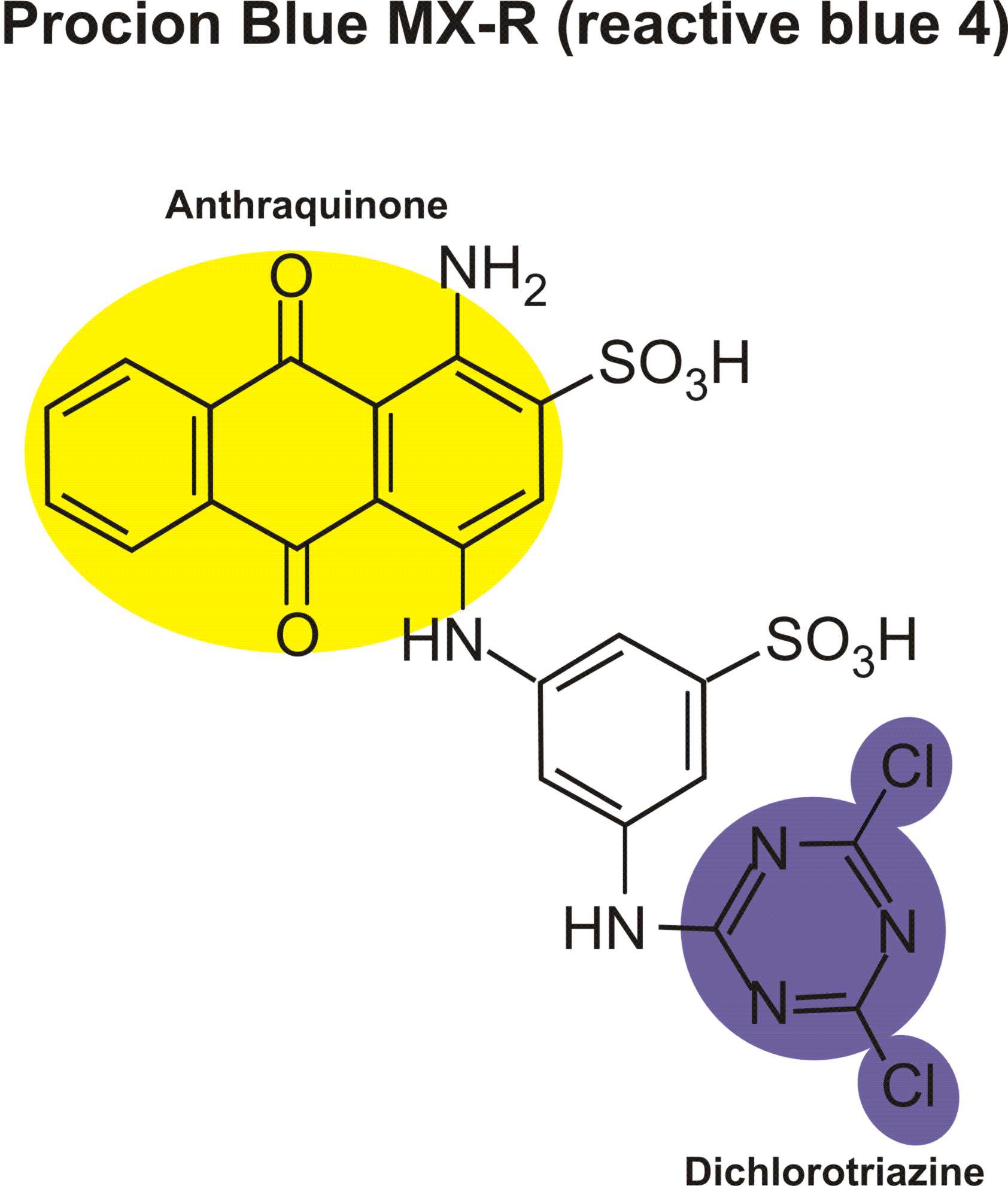

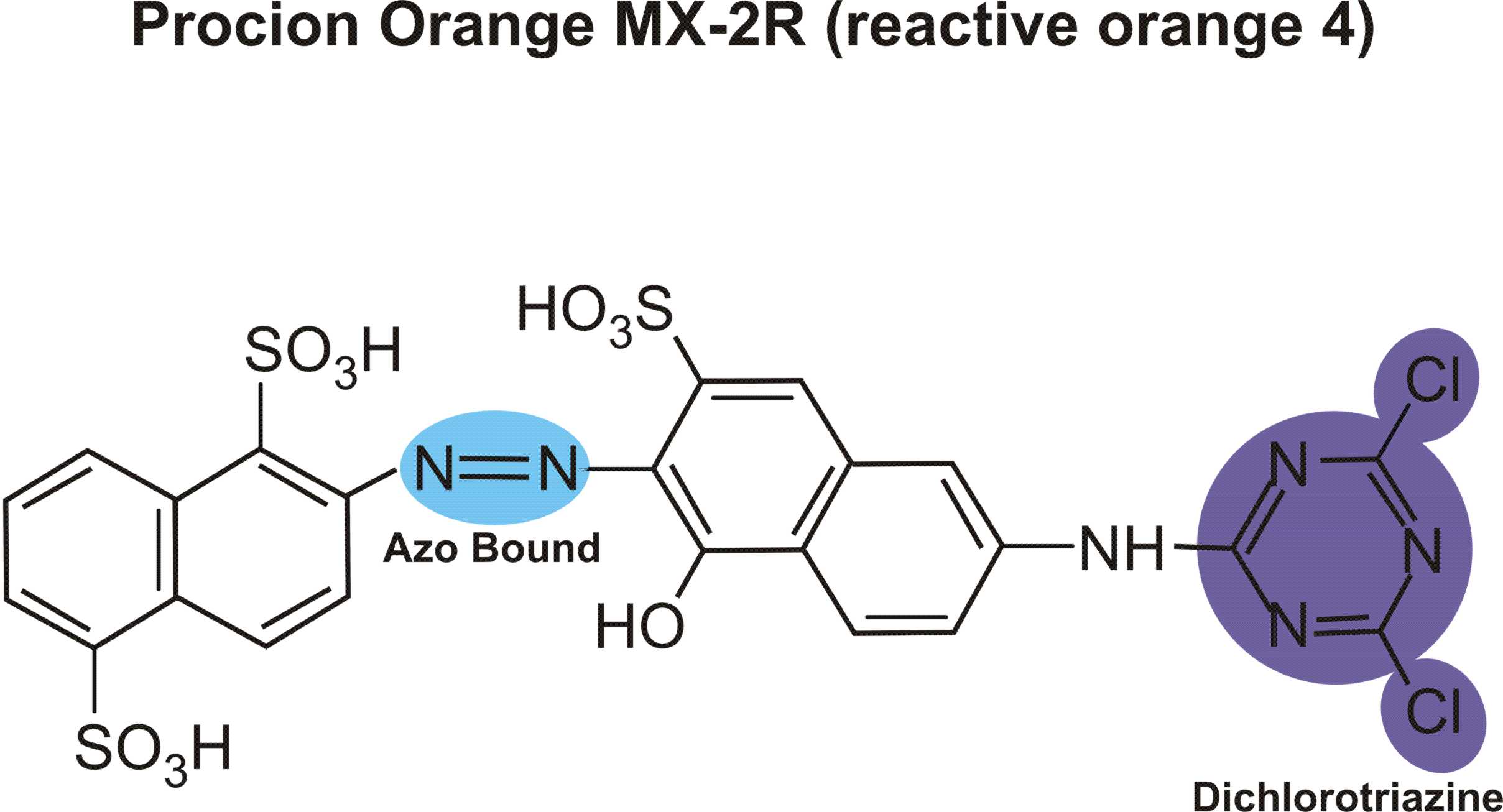

(Don't confuse MX codes that have different color base names! "MX-BR" is meaningless without its base name of "magenta" or "violet" or "red". For example, red MX-G has nothing in common with turquoise MX-G, except that both are dichlorotriazine (Procion MX type) dyes. See "What do the letters and numbers in the code name for a Procion MX type dye mean? " for more information on how to use these codes.)

Scarlet MX-BRA is a rather uninteresting though undeniably useful manufacturer's mix of two dyes; I believe that it is orange MX-2R combined with red MX-5B, which is a good way to mix a halo-free true red, using Procion MX type dyes. It is completely different from and unrelated to boysenberry. Boysenberry 802 is distinctly bluer than fuchsia (red MX-8B), but much redder (or pinker) than reactive violet 14 (whose proper MX code is violet MX-2R). It is a little difficult to dissolve. Surprisingly, boysenberry mixes with tangerine yellow (yellow MX-GR) to make a very good blood red.

It is my best guess that boysenberry is reactive violet 13 (magenta MX-B), but it might be reactive violet 12 (violet MX-4R) or reactive red 74 (pink MX-B), both of which are on the worldwide market for the textile industry. I don't have any samples of either for testing as a comparison.

Did you know that Aljo Manufacturing is now selling the beautiful blue-violet, blue MX-7RX (reactive blue 161), in the US? It's been unavailable here for many years, except for a brief period when it was imported by Scarlet Zebra.

(Please help support this web site. Thank you.)

Thursday, November 01, 2007

1) What are dyes? 2) What is Types of Dyes? 3) How to Prepare Dyes?

any resource ideas for plain white canvas Keds sneakers (blanks for painting, so hopefully cheaper than keds)

Name: Sue

Message: Paula - any resource ideas for plain white canvas Keds sneakers (blanks for painting, so hopefully cheaper than keds)

I've found off-brand cotton canvas shoes at Target that dyed well when soaked in soda ash and then painted with Procion MX dyes. They were not particularly comfortable, since they had no arch support, but they were very inexpensive. Walmart or other discount stores might carry similar shoes. Amazon sells these Cherokee canvas oxfords for $12.99.

Amazon sells white canvas Converse shoes (see link) .

If these are cotton canvas (or hemp canvas), they should dye well, unless they

have had a water-resistant or stain-resistant finish applied to them. (Try

spilling a drop of water on the fabric; if it beads up, it is water-resistant

and thus no good for dyeing.) If you can find them without such surface

finishes, even synthetic-fiber canvases should work well with acrylic fabric

paints such as Lumiere or Dye-Na-Flow. For the greatest durability without

heat-setting these paints, you can add a product called Jacquard AirSet, which

catalyzes the acrylic reaction without

heat.

.

If these are cotton canvas (or hemp canvas), they should dye well, unless they

have had a water-resistant or stain-resistant finish applied to them. (Try

spilling a drop of water on the fabric; if it beads up, it is water-resistant

and thus no good for dyeing.) If you can find them without such surface

finishes, even synthetic-fiber canvases should work well with acrylic fabric

paints such as Lumiere or Dye-Na-Flow. For the greatest durability without

heat-setting these paints, you can add a product called Jacquard AirSet, which

catalyzes the acrylic reaction without

heat.

Keds sells some shoes that are labeled as being stain-resistant: avoid these because they will not dye well. The fact that some are labeled as stain-resistant makes it seem hopeful that the others that are not so labeled are free of this dye-repelling finish. Their white twill shoes seem like a good bet.

(Please help support this web site. Thank you.)

Message: Paula - any resource ideas for plain white canvas Keds sneakers (blanks for painting, so hopefully cheaper than keds)

I've found off-brand cotton canvas shoes at Target that dyed well when soaked in soda ash and then painted with Procion MX dyes. They were not particularly comfortable, since they had no arch support, but they were very inexpensive. Walmart or other discount stores might carry similar shoes. Amazon sells these Cherokee canvas oxfords for $12.99.

Amazon sells white canvas Converse shoes (see link)

.

If these are cotton canvas (or hemp canvas), they should dye well, unless they

have had a water-resistant or stain-resistant finish applied to them. (Try

spilling a drop of water on the fabric; if it beads up, it is water-resistant

and thus no good for dyeing.) If you can find them without such surface

finishes, even synthetic-fiber canvases should work well with acrylic fabric

paints such as Lumiere or Dye-Na-Flow. For the greatest durability without

heat-setting these paints, you can add a product called Jacquard AirSet, which

catalyzes the acrylic reaction without

heat.

.

If these are cotton canvas (or hemp canvas), they should dye well, unless they

have had a water-resistant or stain-resistant finish applied to them. (Try

spilling a drop of water on the fabric; if it beads up, it is water-resistant

and thus no good for dyeing.) If you can find them without such surface

finishes, even synthetic-fiber canvases should work well with acrylic fabric

paints such as Lumiere or Dye-Na-Flow. For the greatest durability without

heat-setting these paints, you can add a product called Jacquard AirSet, which

catalyzes the acrylic reaction without

heat.

Keds sells some shoes that are labeled as being stain-resistant: avoid these because they will not dye well. The fact that some are labeled as stain-resistant makes it seem hopeful that the others that are not so labeled are free of this dye-repelling finish. Their white twill shoes seem like a good bet.

(Please help support this web site. Thank you.)

Thursday, November 29, 2007

I have two all-white Chicago Cubs baseball caps that I'd like to dye a navy blue

Name: John

Message: I have looked through your site, but haven't found this question: I have two all-white Chicago Cubs baseball caps that I'd like to dye a navy blue. (Can you believe out of the hundreds of styles and colors, they don't have a simple all-navy cap? Anyway, I'm totally inept at these kinds of things. How can I dye the caps -- or is there someone who will do it, obviously for a fee?

What fiber are the caps made of? You can't know how–or whether—to dye anything unless you know what fiber it is made of. See my page, "About the Dyes".

Cotton hats can be easily dyed with a cool water fiber reactive dye such as Procion MX dye. I do not recommend all-purpose dye, such as Rit® dye or Tintex® dye, for cotton.

Polyester will not accept ordinary dyes, and I don't think you want to try using the special disperse dyes that are required for dyeing polyester.

Cotton/polyester blends will dye only the cotton portion. An 80%cotton/20% polyester blend will dye well with fiber reactive dye, but a 50%cotton/50%polyester blend will produce a pastel color, not so good for your goal of a dark navy blue, and lower percentages of cotton will dye more poorly still.

Nylon hats can be dyed with acid dyes, including all-purpose dyes, but they must be simmered, up to 185°F (85°C), in a cooking pot with the dye and a little vinegar. (Do not reuse the cooking pot for food after using it for dyeing.) Wool can be dyed exactly like nylon. The plastic parts sometimes used in baseball caps are usually nylon and will also dye with this method. Perhaps unfortunately, so will any nylon-thread embroidery or appliques.

An alternative to dye is the use of fabric paint, which will work on most synthetic fibers almost as well as on natural fibers. Jacquard Dye-Na-Flow [see advertisement below] is a fabric paint that flows like a dye. It will be impossible to get solid color results as smooth and even with any fabric paint as you can get with dye, and the results will tend to wear off much more quickly than a good fabric dye, but the advantage is that it will work on most fibers. However, fibers that have been treated with a stain-resistant or water-repellent coating will accept neither paint nor dyes.

Sorry, I do not know of anyone who will dye your baseball cap for you. It's not a common service these days. Please look at my page on "Where can I find someone to dye my clothing for me?". There are just a couple of companies that are willing to redye clothing from one color to another; whether they will be willing to dye your caps depends on their fiber content. I have seen various navy blue Chicago Cubs caps for sale, but they might not be the style you are looking for.

(Please help support this web site. Thank you.)

Advertisements

Message: I have looked through your site, but haven't found this question: I have two all-white Chicago Cubs baseball caps that I'd like to dye a navy blue. (Can you believe out of the hundreds of styles and colors, they don't have a simple all-navy cap? Anyway, I'm totally inept at these kinds of things. How can I dye the caps -- or is there someone who will do it, obviously for a fee?

What fiber are the caps made of? You can't know how–or whether—to dye anything unless you know what fiber it is made of. See my page, "About the Dyes".

Cotton hats can be easily dyed with a cool water fiber reactive dye such as Procion MX dye. I do not recommend all-purpose dye, such as Rit® dye or Tintex® dye, for cotton.

Polyester will not accept ordinary dyes, and I don't think you want to try using the special disperse dyes that are required for dyeing polyester.

Cotton/polyester blends will dye only the cotton portion. An 80%cotton/20% polyester blend will dye well with fiber reactive dye, but a 50%cotton/50%polyester blend will produce a pastel color, not so good for your goal of a dark navy blue, and lower percentages of cotton will dye more poorly still.

Nylon hats can be dyed with acid dyes, including all-purpose dyes, but they must be simmered, up to 185°F (85°C), in a cooking pot with the dye and a little vinegar. (Do not reuse the cooking pot for food after using it for dyeing.) Wool can be dyed exactly like nylon. The plastic parts sometimes used in baseball caps are usually nylon and will also dye with this method. Perhaps unfortunately, so will any nylon-thread embroidery or appliques.

An alternative to dye is the use of fabric paint, which will work on most synthetic fibers almost as well as on natural fibers. Jacquard Dye-Na-Flow [see advertisement below] is a fabric paint that flows like a dye. It will be impossible to get solid color results as smooth and even with any fabric paint as you can get with dye, and the results will tend to wear off much more quickly than a good fabric dye, but the advantage is that it will work on most fibers. However, fibers that have been treated with a stain-resistant or water-repellent coating will accept neither paint nor dyes.

Sorry, I do not know of anyone who will dye your baseball cap for you. It's not a common service these days. Please look at my page on "Where can I find someone to dye my clothing for me?". There are just a couple of companies that are willing to redye clothing from one color to another; whether they will be willing to dye your caps depends on their fiber content. I have seen various navy blue Chicago Cubs caps for sale, but they might not be the style you are looking for.

(Please help support this web site. Thank you.)

Advertisements

Wednesday, November 28, 2007

planning to dye a sweatshirt that has a silkscreened design. will the dyeing process cause any shrinkage in this kind of garment?

Name: Line

Message: Hi, I'm planning to dye a sweatshirt that has a silkscreened design on it. I think this will work because my sister in law has done other garments like this and I've loved them.

Silkscreened designs are unaffected by dyeing, in my experience, but you must keep the color light enough that the design does not simply seem to disappear, due to loss of contrast.

It's a white sweatshirt - Hanes® Heavyweight cotton poly blend. I have a large on order - will the dyeing process cause any shrinkage in this kind of garment? I hope I didn't miss this on the website - I did do a search.

There are two main classes of dyes for cotton: hot water

dyes, and cool water

dyes. Hot water dyes require nearly boiling water to perform their

best, which will, of course, cause as much cotton shrinkage as is possible. Hot

water dyes are widely available as Rit® Dye, Tintex® Easy Fabric Dye, DEKA® L dye,

etc. However, you should avoid hot water dyes when dyeing cotton clothing,

anyway. In particular, all-purpose

dyes perform poorly on cotton clothing, fading quickly in the laundry,

and (as a bonus) possibly ruining other clothing you wash the dyed garments

with, if you are not meticulous about sorting.

hot water

dyes, and cool water

dyes. Hot water dyes require nearly boiling water to perform their

best, which will, of course, cause as much cotton shrinkage as is possible. Hot

water dyes are widely available as Rit® Dye, Tintex® Easy Fabric Dye, DEKA® L dye,

etc. However, you should avoid hot water dyes when dyeing cotton clothing,

anyway. In particular, all-purpose

dyes perform poorly on cotton clothing, fading quickly in the laundry,

and (as a bonus) possibly ruining other clothing you wash the dyed garments

with, if you are not meticulous about sorting.

In contrast, a good cool water fiber reactive dye will not require boiling water. The most popular of fiber reactive dyes, Procion MX dye, can be used in water as cool as 70°F (21°C), which

will not shrink anything. It will also produce brighter, prettier results than

all-purpose dye can, and will last a hundred times longer in the laundry without

ever requiring you to wash it with similar colors. You will use soda ash to

fix the dye, instead of heat; this works only with fiber reactive dyes, never

with all-purpose dyes. Soda ash is a

common household chemical, found in washing soda and most laundry detergents;

you can buy it from the same company that sells you your Procion MX dye, or you

can get it from your local hardware store in the swimming pools supply

section.

which

will not shrink anything. It will also produce brighter, prettier results than

all-purpose dye can, and will last a hundred times longer in the laundry without

ever requiring you to wash it with similar colors. You will use soda ash to

fix the dye, instead of heat; this works only with fiber reactive dyes, never

with all-purpose dyes. Soda ash is a

common household chemical, found in washing soda and most laundry detergents;

you can buy it from the same company that sells you your Procion MX dye, or you

can get it from your local hardware store in the swimming pools supply

section.

However, the dyeing process absolutely requires a thorough washing afterwards, preferably washing in hot water of 140°F or higher, to remove excess unreacted dye. As you know, cotton does shrink when first washed, especially in hot water. If it is very important to you to maintain the pre-washing size of the shirt, you will have to wash out only in cool water. Cool water does not work nearly as efficiently in washing out fiber reactive dyes, so, if you do not use hot water for your washing out, you will have to be cautious with the garment, washing it separately or only with similar colors, until all of the excess dye has been removed, which could take many, many washings in cool water. It will work fine, though. You can do it. Just be aware that if the dyed clothing is washed in hot water for the first time even a year later, more dye will come out that did not come out in cool water. If you're ever going to wash in hot water, it's as well to do so right after dyeing, so that you know there is no unattached dye left to run in hot water.

As a lazy person, I prefer to buy clothing in the size that will fit even after machine washing and drying. This can save a lot of work over the lifetime of the garment. If I were you, I'd buy one size larger so that I could wash in hot water with impunity.

It is very important to note that while you can dye the cotton in your blended sweatshirt, you cannot dye the polyester. A

50% cotton/50% polyester blend will produce a nice pastel, if you use plenty of

dye. The same dyes will produce a brilliant color on a 100% cotton sweatshirt.

It is almost always preferable to dye a 100% cotton (or 100% rayon or 100% silk)

garment. 50% cotton is fine if you don't mind pastel colors, though. Polyester

will not accept any dyes that work on cotton; it will just stay white. (The

special

dye that will work on polyester requires that you boil the garment

with the dye for an hour, which will ruin many garments! Don't even bother to

try to dye the polyester fiber in your blended clothing.) Hanes does sell sweatshirts that are 100% cotton on the surface

and 80% cotton on the backing, which would be ideal for dyeing, as long as there

is no stain-resistant finish. 80% cotton generally dyes quite

well.

A

50% cotton/50% polyester blend will produce a nice pastel, if you use plenty of

dye. The same dyes will produce a brilliant color on a 100% cotton sweatshirt.

It is almost always preferable to dye a 100% cotton (or 100% rayon or 100% silk)

garment. 50% cotton is fine if you don't mind pastel colors, though. Polyester

will not accept any dyes that work on cotton; it will just stay white. (The

special

dye that will work on polyester requires that you boil the garment

with the dye for an hour, which will ruin many garments! Don't even bother to

try to dye the polyester fiber in your blended clothing.) Hanes does sell sweatshirts that are 100% cotton on the surface

and 80% cotton on the backing, which would be ideal for dyeing, as long as there

is no stain-resistant finish. 80% cotton generally dyes quite

well.

(Please help support this web site. Thank you.)

Message: Hi, I'm planning to dye a sweatshirt that has a silkscreened design on it. I think this will work because my sister in law has done other garments like this and I've loved them.

Silkscreened designs are unaffected by dyeing, in my experience, but you must keep the color light enough that the design does not simply seem to disappear, due to loss of contrast.

It's a white sweatshirt - Hanes® Heavyweight cotton poly blend. I have a large on order - will the dyeing process cause any shrinkage in this kind of garment? I hope I didn't miss this on the website - I did do a search.

There are two main classes of dyes for cotton:

hot water

dyes, and cool water

dyes. Hot water dyes require nearly boiling water to perform their

best, which will, of course, cause as much cotton shrinkage as is possible. Hot

water dyes are widely available as Rit® Dye, Tintex® Easy Fabric Dye, DEKA® L dye,

etc. However, you should avoid hot water dyes when dyeing cotton clothing,

anyway. In particular, all-purpose

dyes perform poorly on cotton clothing, fading quickly in the laundry,

and (as a bonus) possibly ruining other clothing you wash the dyed garments

with, if you are not meticulous about sorting.

hot water

dyes, and cool water

dyes. Hot water dyes require nearly boiling water to perform their

best, which will, of course, cause as much cotton shrinkage as is possible. Hot

water dyes are widely available as Rit® Dye, Tintex® Easy Fabric Dye, DEKA® L dye,

etc. However, you should avoid hot water dyes when dyeing cotton clothing,

anyway. In particular, all-purpose

dyes perform poorly on cotton clothing, fading quickly in the laundry,

and (as a bonus) possibly ruining other clothing you wash the dyed garments

with, if you are not meticulous about sorting.In contrast, a good cool water fiber reactive dye will not require boiling water. The most popular of fiber reactive dyes, Procion MX dye, can be used in water as cool as 70°F (21°C),

which

will not shrink anything. It will also produce brighter, prettier results than

all-purpose dye can, and will last a hundred times longer in the laundry without

ever requiring you to wash it with similar colors. You will use soda ash to

fix the dye, instead of heat; this works only with fiber reactive dyes, never

with all-purpose dyes. Soda ash is a

common household chemical, found in washing soda and most laundry detergents;

you can buy it from the same company that sells you your Procion MX dye, or you

can get it from your local hardware store in the swimming pools supply

section.

which

will not shrink anything. It will also produce brighter, prettier results than

all-purpose dye can, and will last a hundred times longer in the laundry without

ever requiring you to wash it with similar colors. You will use soda ash to

fix the dye, instead of heat; this works only with fiber reactive dyes, never

with all-purpose dyes. Soda ash is a

common household chemical, found in washing soda and most laundry detergents;

you can buy it from the same company that sells you your Procion MX dye, or you

can get it from your local hardware store in the swimming pools supply

section.However, the dyeing process absolutely requires a thorough washing afterwards, preferably washing in hot water of 140°F or higher, to remove excess unreacted dye. As you know, cotton does shrink when first washed, especially in hot water. If it is very important to you to maintain the pre-washing size of the shirt, you will have to wash out only in cool water. Cool water does not work nearly as efficiently in washing out fiber reactive dyes, so, if you do not use hot water for your washing out, you will have to be cautious with the garment, washing it separately or only with similar colors, until all of the excess dye has been removed, which could take many, many washings in cool water. It will work fine, though. You can do it. Just be aware that if the dyed clothing is washed in hot water for the first time even a year later, more dye will come out that did not come out in cool water. If you're ever going to wash in hot water, it's as well to do so right after dyeing, so that you know there is no unattached dye left to run in hot water.

As a lazy person, I prefer to buy clothing in the size that will fit even after machine washing and drying. This can save a lot of work over the lifetime of the garment. If I were you, I'd buy one size larger so that I could wash in hot water with impunity.

It is very important to note that while you can dye the cotton in your blended sweatshirt, you cannot dye the polyester.

A

50% cotton/50% polyester blend will produce a nice pastel, if you use plenty of

dye. The same dyes will produce a brilliant color on a 100% cotton sweatshirt.

It is almost always preferable to dye a 100% cotton (or 100% rayon or 100% silk)

garment. 50% cotton is fine if you don't mind pastel colors, though. Polyester

will not accept any dyes that work on cotton; it will just stay white. (The

special

dye that will work on polyester requires that you boil the garment

with the dye for an hour, which will ruin many garments! Don't even bother to

try to dye the polyester fiber in your blended clothing.) Hanes does sell sweatshirts that are 100% cotton on the surface

and 80% cotton on the backing, which would be ideal for dyeing, as long as there

is no stain-resistant finish. 80% cotton generally dyes quite

well.

A

50% cotton/50% polyester blend will produce a nice pastel, if you use plenty of

dye. The same dyes will produce a brilliant color on a 100% cotton sweatshirt.

It is almost always preferable to dye a 100% cotton (or 100% rayon or 100% silk)

garment. 50% cotton is fine if you don't mind pastel colors, though. Polyester

will not accept any dyes that work on cotton; it will just stay white. (The

special

dye that will work on polyester requires that you boil the garment

with the dye for an hour, which will ruin many garments! Don't even bother to

try to dye the polyester fiber in your blended clothing.) Hanes does sell sweatshirts that are 100% cotton on the surface

and 80% cotton on the backing, which would be ideal for dyeing, as long as there

is no stain-resistant finish. 80% cotton generally dyes quite

well.(Please help support this web site. Thank you.)

Tuesday, November 27, 2007

How can I dye blue overalls to make them coral?

Name: lukas

Message: hi I ve got blue overhaulls and want to dye them Coral,what do I do,what two colors give Coral

Please help urgent

Regards

Sorry, it can't be done. The color coral does not contain any blue, so overdyeing blue overalls to create coral is impossible.

If you want coral overalls, and cannot find any in the store, you must first buy some overalls that are white, and made of 100% cotton. You could overdye a light yellow to make coral, or a light pink, but no other color. (Here's a link for buying white cotton overalls from Amazon.)

Buy some orange fiber reactive dye, such as Procion MX dye. (Avoid all-purpose dye, because it is hard to apply—you have to boil it for best results—and fades quickly in the laundry.) Along with your Procion MX dye, buy some salt and soda ash, and follow instructions for dyeing in the washing machine; see "How can I dye clothing or fabric in the washing machine?".

The trouble is that dye is transparent. It cannot cover up a darker color. Whatever color is already there in the garment will show through any dye that you apply.

If you have white overalls, it is easy to dye them coral. All you need is to dye them a pale shade of reddish orange. To produce a pale shade, you use a small quantity of dye. Although it is generally recommended that you use one teaspoon of this dye per pound of fabric to get a pale shade, for coral you should use less than this, perhaps 1/4 teaspoon to 1/2 teaspoon per pound of fabric. You can buy good Procion MX dye and soda ash from any of the suppliers listed on my page, Sources for Dyeing Supplies Around the World. (Here is a link for ordering orange Procion MX dye through Amazon, and another for buying soda ash.)

It might be possible to turn your blue overalls white by bleaching them, but it is likely that you will never be able to get out all of the color. Most likely, you will be able to produce a pale blue, which is good for overdyeing many colors, but no good at all for producing a nice clear coral.

The best colors for overdyeing blue overalls and blue jeans are all darker than the original color: navy blue, dark brown, deep purple, dark forest green, or black.

(Please help support this web site. Thank you.)

Message: hi I ve got blue overhaulls and want to dye them Coral,what do I do,what two colors give Coral

Please help urgent

Regards

Sorry, it can't be done. The color coral does not contain any blue, so overdyeing blue overalls to create coral is impossible.

If you want coral overalls, and cannot find any in the store, you must first buy some overalls that are white, and made of 100% cotton. You could overdye a light yellow to make coral, or a light pink, but no other color. (Here's a link for buying white cotton overalls from Amazon.)

Buy some orange fiber reactive dye, such as Procion MX dye. (Avoid all-purpose dye, because it is hard to apply—you have to boil it for best results—and fades quickly in the laundry.) Along with your Procion MX dye, buy some salt and soda ash, and follow instructions for dyeing in the washing machine; see "How can I dye clothing or fabric in the washing machine?".

The trouble is that dye is transparent. It cannot cover up a darker color. Whatever color is already there in the garment will show through any dye that you apply.

If you have white overalls, it is easy to dye them coral. All you need is to dye them a pale shade of reddish orange. To produce a pale shade, you use a small quantity of dye. Although it is generally recommended that you use one teaspoon of this dye per pound of fabric to get a pale shade, for coral you should use less than this, perhaps 1/4 teaspoon to 1/2 teaspoon per pound of fabric. You can buy good Procion MX dye and soda ash from any of the suppliers listed on my page, Sources for Dyeing Supplies Around the World. (Here is a link for ordering orange Procion MX dye through Amazon, and another for buying soda ash.)

It might be possible to turn your blue overalls white by bleaching them, but it is likely that you will never be able to get out all of the color. Most likely, you will be able to produce a pale blue, which is good for overdyeing many colors, but no good at all for producing a nice clear coral.

The best colors for overdyeing blue overalls and blue jeans are all darker than the original color: navy blue, dark brown, deep purple, dark forest green, or black.

(Please help support this web site. Thank you.)

Monday, November 26, 2007

will the cold prevent the dyes working?

Name: Helen Conway (downthewell.blogspot.com)

Message: I want to try hand dyeing a gradation of fabrics for quilting. I think that Cold water Dylon is the easiest for me to get hold of here in the UK. However, I am concerned about temperature. I have a tiny kitchen and will have to do it all out in the garage over the Christmas period which in the UK translates to just above freezing temperatures. I can wear layers but will the cold prevent the dyes working?

Yes, it will. It's good that you're thinking about this in advance. Dylon Cold Water Dye is a fiber reactive dye that does not require nearly as much warmth as, say, an all-purpose dye (which should be boiled with the fabric), but it does require some. Most of the colors in Dylon Cold Water Dye are Procion MX dyes, though a few are Drimarene K or Remazol type dyes. (See the post, "more about Dylon Cold Water Dyes ", in the Dye Forum on my site). The minimum temperature requirement is roughly 21°C (70°F), for dyes left to react with fabric overnight or longer; warmer temperatures work fine, too, and reduce the required amount of time. The reaction between fiber reactive dye and fabric can take place only in the presence of moisture, a high-pH chemical such as soda ash (also known as "Dylon Cold Fix"), and adequate warmth.

There are many different ways to heat up your dye reactions. If you're doing direct dye application, the simplest is to wrap them up so that you can safely take them into a warmer part of the house overnight. You can wrap each piece with plastic wrap, to prevent one part of the fabric from touching another when you roll it up, and then place the whole roll into a plastic bag, and carry the wrapped bundles in plastic buckets or boxes.

If you are dyeing in small buckets, you can fill your sink, or a large insulated cooler, with very hot tap water, and rest your buckets in there. (Don't fill the cooler so full of water that the buckets float; they might tip over, which would be a disaster.) The insulated cooler is ideal because it will hold the heat for hours. If you are dyeing in plastic bags, you can place several in each of a number of plastic buckets or bowls to heat in the same way. Alternatively, you can double-bag them in the sturdier zipper-top plastic bags used for freezer storage, and float those in the warm or hot water.

If you're working on a table, you can place an electric heating blanket or waterproof heated mattress pad (preferably one plugged into a ground fault circuit interrupter!) on the table, then cover that with a sturdy plastic sheet or tablecloth, and lay out your work on top of that, or do the reverse, laying your work out on the table, covering that with a reliable layer of sturdy thin plastic, with the electric blanket on top of that.

Avoid Dylon® Multi Purpose dye. Like Rit® dye and Tintex® Easy Fabric Dye, it is an all-purpose

dye which does not produce very long-lasting results on cotton, and it

requires high heat (87°C) to attach as well as possible to the fabric.

Dylon Cold Dye, Dylon Machine Dye, and Dylon Permanent dye (the latter available

in North America) all perform much better, since they are fiber reactive

dyes.

dye. Like Rit® dye and Tintex® Easy Fabric Dye, it is an all-purpose

dye which does not produce very long-lasting results on cotton, and it

requires high heat (87°C) to attach as well as possible to the fabric.

Dylon Cold Dye, Dylon Machine Dye, and Dylon Permanent dye (the latter available

in North America) all perform much better, since they are fiber reactive

dyes.

Dylon Cold Water dyes bond well to cotton fabric, since they are mostly Procion MX dyes, but they can be frustrating to work with, since the pure unmixed Procion MX dyes are not supplied in this line, but only mixtures of dye colors, designed to meet current fashion standards. There are no ideal primary colors in the Dylon Cold Dye line for mixing your own colors, because all have had some other color of dye added, which will cause your mixtures to be duller in color. Also, the tiny 5-gram tins are really very expensive, considering how little they will dye, only about 200 grams of fabric per tin, and only 100 grams for black. You will have to buy a great many of them if you are planning on doing much dyeing.

There are better dyes that you can buy, instead of Dylon dyes, if

you are going to be mixing your colors or doing color gradations. In the UK,

there are several good sources for buying fiber reactive dye by mail-order. See

my page of Sources

for Dyeing Supplies Around the World, scrolling down to the

section on Europe. For example, Fibrecrafts/George Weil sells Procion MX dyes

for £8.40 for 50 grams of dye, equivalent to at least ten of the tiny tins

of Dylon Cold, which each cost about £1.89. (It may be a better value

still, since the Dylon dye powders are likely to be more dilute than the Procion

MX dye powders sold by Fibrecrafts.) Fibrecrafts sells a good range of the pure unmixed

single-hue Procion MX dyes, which many dyers find to be much more

satisfying for use in color mixing and color gradations. I recommend that, at

minimum, you purchase lemon yellow, vibrant magenta or brilliant pink, brilliant

turquoise, and black; I recommend also that you get some golden yellow and

indigo navy. Also consider the other good mail-order suppliers listed on my page

of Sources

for Dyeing Supplies Around the World. You can buy soda ash

locally or from your mail-order dye supplier for much less money than Dylon Cold

Fix, as well, although they are identical substances.

if

you are going to be mixing your colors or doing color gradations. In the UK,

there are several good sources for buying fiber reactive dye by mail-order. See

my page of Sources

for Dyeing Supplies Around the World, scrolling down to the

section on Europe. For example, Fibrecrafts/George Weil sells Procion MX dyes

for £8.40 for 50 grams of dye, equivalent to at least ten of the tiny tins

of Dylon Cold, which each cost about £1.89. (It may be a better value

still, since the Dylon dye powders are likely to be more dilute than the Procion

MX dye powders sold by Fibrecrafts.) Fibrecrafts sells a good range of the pure unmixed

single-hue Procion MX dyes, which many dyers find to be much more

satisfying for use in color mixing and color gradations. I recommend that, at

minimum, you purchase lemon yellow, vibrant magenta or brilliant pink, brilliant

turquoise, and black; I recommend also that you get some golden yellow and

indigo navy. Also consider the other good mail-order suppliers listed on my page

of Sources

for Dyeing Supplies Around the World. You can buy soda ash

locally or from your mail-order dye supplier for much less money than Dylon Cold

Fix, as well, although they are identical substances.

(Please help support this web site. Thank you.)

Message: I want to try hand dyeing a gradation of fabrics for quilting. I think that Cold water Dylon is the easiest for me to get hold of here in the UK. However, I am concerned about temperature. I have a tiny kitchen and will have to do it all out in the garage over the Christmas period which in the UK translates to just above freezing temperatures. I can wear layers but will the cold prevent the dyes working?

Yes, it will. It's good that you're thinking about this in advance. Dylon Cold Water Dye is a fiber reactive dye that does not require nearly as much warmth as, say, an all-purpose dye (which should be boiled with the fabric), but it does require some. Most of the colors in Dylon Cold Water Dye are Procion MX dyes, though a few are Drimarene K or Remazol type dyes. (See the post, "more about Dylon Cold Water Dyes ", in the Dye Forum on my site). The minimum temperature requirement is roughly 21°C (70°F), for dyes left to react with fabric overnight or longer; warmer temperatures work fine, too, and reduce the required amount of time. The reaction between fiber reactive dye and fabric can take place only in the presence of moisture, a high-pH chemical such as soda ash (also known as "Dylon Cold Fix"), and adequate warmth.

There are many different ways to heat up your dye reactions. If you're doing direct dye application, the simplest is to wrap them up so that you can safely take them into a warmer part of the house overnight. You can wrap each piece with plastic wrap, to prevent one part of the fabric from touching another when you roll it up, and then place the whole roll into a plastic bag, and carry the wrapped bundles in plastic buckets or boxes.

If you are dyeing in small buckets, you can fill your sink, or a large insulated cooler, with very hot tap water, and rest your buckets in there. (Don't fill the cooler so full of water that the buckets float; they might tip over, which would be a disaster.) The insulated cooler is ideal because it will hold the heat for hours. If you are dyeing in plastic bags, you can place several in each of a number of plastic buckets or bowls to heat in the same way. Alternatively, you can double-bag them in the sturdier zipper-top plastic bags used for freezer storage, and float those in the warm or hot water.

If you're working on a table, you can place an electric heating blanket or waterproof heated mattress pad (preferably one plugged into a ground fault circuit interrupter!) on the table, then cover that with a sturdy plastic sheet or tablecloth, and lay out your work on top of that, or do the reverse, laying your work out on the table, covering that with a reliable layer of sturdy thin plastic, with the electric blanket on top of that.

Avoid Dylon® Multi Purpose

dye. Like Rit® dye and Tintex® Easy Fabric Dye, it is an all-purpose

dye which does not produce very long-lasting results on cotton, and it

requires high heat (87°C) to attach as well as possible to the fabric.

Dylon Cold Dye, Dylon Machine Dye, and Dylon Permanent dye (the latter available

in North America) all perform much better, since they are fiber reactive

dyes.

dye. Like Rit® dye and Tintex® Easy Fabric Dye, it is an all-purpose

dye which does not produce very long-lasting results on cotton, and it

requires high heat (87°C) to attach as well as possible to the fabric.

Dylon Cold Dye, Dylon Machine Dye, and Dylon Permanent dye (the latter available

in North America) all perform much better, since they are fiber reactive

dyes.Dylon Cold Water dyes bond well to cotton fabric, since they are mostly Procion MX dyes, but they can be frustrating to work with, since the pure unmixed Procion MX dyes are not supplied in this line, but only mixtures of dye colors, designed to meet current fashion standards. There are no ideal primary colors in the Dylon Cold Dye line for mixing your own colors, because all have had some other color of dye added, which will cause your mixtures to be duller in color. Also, the tiny 5-gram tins are really very expensive, considering how little they will dye, only about 200 grams of fabric per tin, and only 100 grams for black. You will have to buy a great many of them if you are planning on doing much dyeing.

There are better dyes that you can buy, instead of Dylon dyes,

if

you are going to be mixing your colors or doing color gradations. In the UK,

there are several good sources for buying fiber reactive dye by mail-order. See

my page of Sources

for Dyeing Supplies Around the World, scrolling down to the

section on Europe. For example, Fibrecrafts/George Weil sells Procion MX dyes

for £8.40 for 50 grams of dye, equivalent to at least ten of the tiny tins

of Dylon Cold, which each cost about £1.89. (It may be a better value

still, since the Dylon dye powders are likely to be more dilute than the Procion

MX dye powders sold by Fibrecrafts.) Fibrecrafts sells a good range of the pure unmixed

single-hue Procion MX dyes, which many dyers find to be much more

satisfying for use in color mixing and color gradations. I recommend that, at

minimum, you purchase lemon yellow, vibrant magenta or brilliant pink, brilliant

turquoise, and black; I recommend also that you get some golden yellow and

indigo navy. Also consider the other good mail-order suppliers listed on my page

of Sources

for Dyeing Supplies Around the World. You can buy soda ash

locally or from your mail-order dye supplier for much less money than Dylon Cold

Fix, as well, although they are identical substances.

if

you are going to be mixing your colors or doing color gradations. In the UK,

there are several good sources for buying fiber reactive dye by mail-order. See

my page of Sources

for Dyeing Supplies Around the World, scrolling down to the

section on Europe. For example, Fibrecrafts/George Weil sells Procion MX dyes

for £8.40 for 50 grams of dye, equivalent to at least ten of the tiny tins

of Dylon Cold, which each cost about £1.89. (It may be a better value

still, since the Dylon dye powders are likely to be more dilute than the Procion

MX dye powders sold by Fibrecrafts.) Fibrecrafts sells a good range of the pure unmixed

single-hue Procion MX dyes, which many dyers find to be much more

satisfying for use in color mixing and color gradations. I recommend that, at

minimum, you purchase lemon yellow, vibrant magenta or brilliant pink, brilliant

turquoise, and black; I recommend also that you get some golden yellow and

indigo navy. Also consider the other good mail-order suppliers listed on my page

of Sources

for Dyeing Supplies Around the World. You can buy soda ash

locally or from your mail-order dye supplier for much less money than Dylon Cold

Fix, as well, although they are identical substances.(Please help support this web site. Thank you.)

Sunday, November 25, 2007

My tub is now a nice shade of blue and scrubbing it with Ajax is NOT helping. Any ideas on how I can get it off

Name: Elisheva

Message: My work space right now is my bathroom...My tub is now a nice shade of blue and scrubbing it with Ajax is NOT helping. Any ideas on how I can get it off?

What is "it" that you need to get off? Rit or Deka all-purpose dye, fabric paint, Procion MX dye, or what? Did you immersion-dye in the bathtub, or just have some splashing from your dye bucket?

oops, sorry I forgot that detail. this is MX dye that got all over due to me washing out the shelf I was using to dye the items, spilling out dye at the bottom of my "project box" AND washing that out frequently...and last but not least, taking off rubber brands and rinsing out each and every item before I threw it into the wash (and that was about 150 things...)

Wow, that's not a problem I've ever seen before. Wherever I've lived, I've only ever had old-fashioned bathtubs with a porcelain finish over cast iron. Until the surface gloss gets worn off (and my current bathtub is sixty years old and still plenty glossy), the porcelain absolutely does not stain with Procion MX dyes. Soap scum or dirt on the surface of the tub will pick up dye, but that's easily removed, obviously not your problem since you've already tried scouring powder without success.

Presumably your bathtub is made of a more "modern", cheaper material, unless it's porcelain with the glossy surface all worn off, or a tub that was refinished some time ago. It might be made of fiberglass, or acrylic. Neither of these will react with Procion MX dye, the way that cellulose (cotton, rayon, or wood) or protein (wool or silk) might do. What I'm afraid of is that one of these might have a more porous nature. If it has actually absorbed the dye into itself, it will be much harder to remove—as you have already observed.

The first step is to scrub as thoroughly as possible,

using a bleach-containing powder, such as your Ajax. Since that has failed,

you'll want to try something else.

possible,

using a bleach-containing powder, such as your Ajax. Since that has failed,

you'll want to try something else.

If your bathtub has been refinished, or if it is made of fiberglass or acrylic, you may need to stick to whatever cleaners are recommended by the manufacturer. If you are renting, the only way to find out if this is the case is to ask the apartment management.

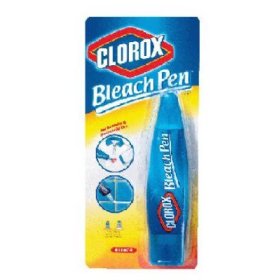

If the material your tub is made of does not react badly to chlorine bleach, you could probably use that to break up and decolorize the dye molecules. However, I've read that some bathtubs develop an ugly reddish-brown stain when treated with bleach. You should test a small area before treating much of your tub with bleach. (According to the Clorox company, you can use "Clorox 2 Bleach for Colors", which is a perborate-based laundry cleaner that liberates peroxide, to remove reddish-brown bathtub stains produced by bleach-containing cleansers.)

Be aware that, for all its familiarity, chlorine

bleach

chlorine

bleach

(active

ingredient: hypochlorite) is a dangerous, toxic chemical. Wear reusable

housecleaning rubber gloves, rather than the thin disposable latex gloves that

often get holes in them. Use fans to provide good ventilation. If too much

exposure to the fumes from the bleach is inevitable, wear a properly-fitting

respirator, outfitted with with acid gas cartridges, to protect you from

breathing the bleach

fumes.

(active

ingredient: hypochlorite) is a dangerous, toxic chemical. Wear reusable

housecleaning rubber gloves, rather than the thin disposable latex gloves that

often get holes in them. Use fans to provide good ventilation. If too much

exposure to the fumes from the bleach is inevitable, wear a properly-fitting

respirator, outfitted with with acid gas cartridges, to protect you from

breathing the bleach

fumes.

How to keep the bleach on the surface long enough to fully act? You might put a rag on the surface and dampen it with liquid bleach, or for small areas you could use the thickened bleach in a Clorox Bleach Pen, or for larger areas you could apply a dishwasher detergent whose label claims "with bleach" and whose ingredients include hypochlorite. Be very careful to avoid any situation in which the bleach might become mixed with any other cleaner, which might contain ammonia (producing deadly chloramine gas), or with any acid such as vinegar or toilet cleaner (producing deadly chlorine gas). Leave your bleach to act for some time, then rinse thoroughly. Be aware that this treatment can damage the grout between floor tiles.

(Please help support this web site. Thank you.)

Message: My work space right now is my bathroom...My tub is now a nice shade of blue and scrubbing it with Ajax is NOT helping. Any ideas on how I can get it off?

What is "it" that you need to get off? Rit or Deka all-purpose dye, fabric paint, Procion MX dye, or what? Did you immersion-dye in the bathtub, or just have some splashing from your dye bucket?

oops, sorry I forgot that detail. this is MX dye that got all over due to me washing out the shelf I was using to dye the items, spilling out dye at the bottom of my "project box" AND washing that out frequently...and last but not least, taking off rubber brands and rinsing out each and every item before I threw it into the wash (and that was about 150 things...)

Wow, that's not a problem I've ever seen before. Wherever I've lived, I've only ever had old-fashioned bathtubs with a porcelain finish over cast iron. Until the surface gloss gets worn off (and my current bathtub is sixty years old and still plenty glossy), the porcelain absolutely does not stain with Procion MX dyes. Soap scum or dirt on the surface of the tub will pick up dye, but that's easily removed, obviously not your problem since you've already tried scouring powder without success.

Presumably your bathtub is made of a more "modern", cheaper material, unless it's porcelain with the glossy surface all worn off, or a tub that was refinished some time ago. It might be made of fiberglass, or acrylic. Neither of these will react with Procion MX dye, the way that cellulose (cotton, rayon, or wood) or protein (wool or silk) might do. What I'm afraid of is that one of these might have a more porous nature. If it has actually absorbed the dye into itself, it will be much harder to remove—as you have already observed.

The first step is to scrub as thoroughly as

possible,

using a bleach-containing powder, such as your Ajax. Since that has failed,

you'll want to try something else.

possible,

using a bleach-containing powder, such as your Ajax. Since that has failed,

you'll want to try something else.If your bathtub has been refinished, or if it is made of fiberglass or acrylic, you may need to stick to whatever cleaners are recommended by the manufacturer. If you are renting, the only way to find out if this is the case is to ask the apartment management.

If the material your tub is made of does not react badly to chlorine bleach, you could probably use that to break up and decolorize the dye molecules. However, I've read that some bathtubs develop an ugly reddish-brown stain when treated with bleach. You should test a small area before treating much of your tub with bleach. (According to the Clorox company, you can use "Clorox 2 Bleach for Colors", which is a perborate-based laundry cleaner that liberates peroxide, to remove reddish-brown bathtub stains produced by bleach-containing cleansers.)

Be aware that, for all its familiarity,

chlorine

bleach

chlorine

bleach

(active

ingredient: hypochlorite) is a dangerous, toxic chemical. Wear reusable

housecleaning rubber gloves, rather than the thin disposable latex gloves that

often get holes in them. Use fans to provide good ventilation. If too much

exposure to the fumes from the bleach is inevitable, wear a properly-fitting

respirator, outfitted with with acid gas cartridges, to protect you from

breathing the bleach

fumes.

(active

ingredient: hypochlorite) is a dangerous, toxic chemical. Wear reusable

housecleaning rubber gloves, rather than the thin disposable latex gloves that

often get holes in them. Use fans to provide good ventilation. If too much

exposure to the fumes from the bleach is inevitable, wear a properly-fitting

respirator, outfitted with with acid gas cartridges, to protect you from

breathing the bleach

fumes.

How to keep the bleach on the surface long enough to fully act? You might put a rag on the surface and dampen it with liquid bleach, or for small areas you could use the thickened bleach in a Clorox Bleach Pen, or for larger areas you could apply a dishwasher detergent whose label claims "with bleach" and whose ingredients include hypochlorite. Be very careful to avoid any situation in which the bleach might become mixed with any other cleaner, which might contain ammonia (producing deadly chloramine gas), or with any acid such as vinegar or toilet cleaner (producing deadly chlorine gas). Leave your bleach to act for some time, then rinse thoroughly. Be aware that this treatment can damage the grout between floor tiles.

(Please help support this web site. Thank you.)

Saturday, November 24, 2007

I received a bleach stain on my beige cotton sweater. I would like to dye the entire sweater. Can this be done?

Name: Lisa

Message: I received a bleach stain on my beige cotton sweater. I would like to dye the entire sweater. Can this be done? If I dye the sweater, I want the entire sweater to dye, including the bleach stain.

This is a frequently asked question on this site: Help! I ruined clothing by spattering bleach. How can I fix it?

The problem with dyeing the sweater to cover it up is that dye is transparent,

so the bleached spot will inevitably come out a lighter color than the rest of

the sweater. If the region affected is small, you can try covering it with a

fabric

marker , and then if necessary overdyeing a darker color, but if the

stain is large, the only way to really cover it up would be to not even try to

get a perfectly smooth solid color, but instead try low water

immersion dyeing or even tie-dyeing to

minimize its effect.

transparent,

so the bleached spot will inevitably come out a lighter color than the rest of

the sweater. If the region affected is small, you can try covering it with a

fabric

marker , and then if necessary overdyeing a darker color, but if the

stain is large, the only way to really cover it up would be to not even try to

get a perfectly smooth solid color, but instead try low water

immersion dyeing or even tie-dyeing to

minimize its effect.

(Please help support this web site. Thank you.)

Message: I received a bleach stain on my beige cotton sweater. I would like to dye the entire sweater. Can this be done? If I dye the sweater, I want the entire sweater to dye, including the bleach stain.

This is a frequently asked question on this site: Help! I ruined clothing by spattering bleach. How can I fix it?

The problem with dyeing the sweater to cover it up is that dye is

transparent,

so the bleached spot will inevitably come out a lighter color than the rest of

the sweater. If the region affected is small, you can try covering it with a

fabric

marker , and then if necessary overdyeing a darker color, but if the

stain is large, the only way to really cover it up would be to not even try to

get a perfectly smooth solid color, but instead try low water

immersion dyeing or even tie-dyeing to

minimize its effect.

transparent,

so the bleached spot will inevitably come out a lighter color than the rest of

the sweater. If the region affected is small, you can try covering it with a

fabric

marker , and then if necessary overdyeing a darker color, but if the

stain is large, the only way to really cover it up would be to not even try to

get a perfectly smooth solid color, but instead try low water

immersion dyeing or even tie-dyeing to

minimize its effect.(Please help support this web site. Thank you.)

Friday, November 23, 2007

toxicity and environmental damage associated with logwood and other natural dyes

Name: Deborah

Message: I've just started to experiment with natural dyeing. I've done some research about the toxicity of mordants and dye stuffs, but I have not heard about the problem of hematein derived from logwood. Is this also an environmental problem? Is there a source that you can recommend for more information about toxicity and/or environmental damage caused by natural dyeing? I have already read Jim Lile's and Jenny Dean's books, as well as the information from aurorasilk.com.

Books and websites about natural dyes tend not to consider toxicity as a topic. Many neglect or groundlessly minimize the dangers of even such serious health hazards such as chrome, copper, and tin mordants. In order to research this topic, it is necessary to search for specific information from other sources about chemicals. If you know the name of the active principle in the dye, in this case hematein as the active ingredient in logwood, you can often find further information.

Hemetein, the oxidized form

of hematoxylin (Colour Index Natural Black 1), in addition to its use as a

textile dye, is an important stain for use in cytology. Here is a link to

an MSDS for hematein, which identifies it as having

a health hazard rating of 2 (where 0 is harmless and 4 is the maximum). It says,

among other

things,

form

of hematoxylin (Colour Index Natural Black 1), in addition to its use as a

textile dye, is an important stain for use in cytology. Here is a link to

an MSDS for hematein, which identifies it as having

a health hazard rating of 2 (where 0 is harmless and 4 is the maximum). It says,

among other

things,

Unfortunately, the MSDS says little about ecological hazards. Whatever harm may be posed ecologically by this material, it must be vanishingly small in comparison to its use in its heyday, when logwood plus iron was the most reliable black dye commercially available, before the introduction of modern synthetic dyes. Clear-cutting of Brazilian forests for logwood production undoubtedly resulted in much environmental damage. I have no idea whether logwood harvesting is currently practiced in an environmentally harmful way. [Followup: "Logwood from Aurora Silk is supposed to come from an environmentally and socially sustainable project."]

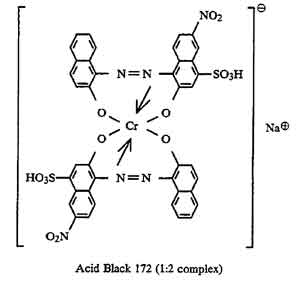

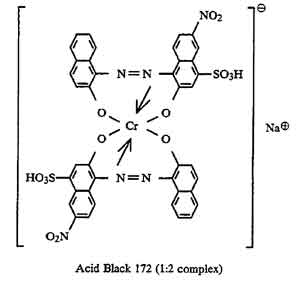

As long as you are steering clear of dangerous mordants such as hexavalent chromium (potassium dichromate, a

known human carcinogen) or tin, you will probably be safe enough with quite

ordinary precautions. Always wear a properly-fitting dust mask or respirator

when working with dye powder; never reuse dyepots or other implements for food;

wear a lab coat or apron to protect clothing, goggles to protect the eyes if

splashing is possible, and always wear reliable gloves while dyeing. (Some

advise against the use of a dust mask, recommending only a NIOSH-approved toxic

dust respirator.) I do not feel that these precautions are sufficient for

working with chrome mordants, which are far too unsafe, in my opinion, for use

in the home dye studio. Hematein is not nearly as hazardous as a chrome mordant.

Prechromed synthetic dyes are safer than chrome mordant because smaller

quantities of chromium are involved, and (more importantly) because they are in

the much safer trivalent form of chromium.

a

known human carcinogen) or tin, you will probably be safe enough with quite

ordinary precautions. Always wear a properly-fitting dust mask or respirator

when working with dye powder; never reuse dyepots or other implements for food;

wear a lab coat or apron to protect clothing, goggles to protect the eyes if

splashing is possible, and always wear reliable gloves while dyeing. (Some

advise against the use of a dust mask, recommending only a NIOSH-approved toxic

dust respirator.) I do not feel that these precautions are sufficient for

working with chrome mordants, which are far too unsafe, in my opinion, for use

in the home dye studio. Hematein is not nearly as hazardous as a chrome mordant.

Prechromed synthetic dyes are safer than chrome mordant because smaller

quantities of chromium are involved, and (more importantly) because they are in

the much safer trivalent form of chromium.

Many dyers believe all natural dyes to be completely safe, but in fact this is often not the case. Besides hematein, there are other toxic natural dyes as well. For example, the dyes alizarin and purpurin, derived from madder, are associated with kidney damage in animal experiments. Lily-of-the-valley, sometimes used for a pale green, is certainly toxic, as is bloodroot. The leaves of rhubarb contain toxic oxalic acid. Even relatively non-toxic dyes such as cochineal are associated with allergies, especially among the workers who prepare them. However, I think that all of these are unlikely to be a problem for the careful dyer, who takes appropriate precautions and does not do anything that will result in breathing, eating, or otherwise consuming dyestuffs.

(Please help support this web site. Thank you.)

Message: I've just started to experiment with natural dyeing. I've done some research about the toxicity of mordants and dye stuffs, but I have not heard about the problem of hematein derived from logwood. Is this also an environmental problem? Is there a source that you can recommend for more information about toxicity and/or environmental damage caused by natural dyeing? I have already read Jim Lile's and Jenny Dean's books, as well as the information from aurorasilk.com.

Books and websites about natural dyes tend not to consider toxicity as a topic. Many neglect or groundlessly minimize the dangers of even such serious health hazards such as chrome, copper, and tin mordants. In order to research this topic, it is necessary to search for specific information from other sources about chemicals. If you know the name of the active principle in the dye, in this case hematein as the active ingredient in logwood, you can often find further information.

Hemetein, the oxidized

form

of hematoxylin (Colour Index Natural Black 1), in addition to its use as a

textile dye, is an important stain for use in cytology. Here is a link to

an MSDS for hematein, which identifies it as having

a health hazard rating of 2 (where 0 is harmless and 4 is the maximum). It says,

among other

things,

form

of hematoxylin (Colour Index Natural Black 1), in addition to its use as a

textile dye, is an important stain for use in cytology. Here is a link to

an MSDS for hematein, which identifies it as having

a health hazard rating of 2 (where 0 is harmless and 4 is the maximum). It says,

among other

things,"After contact with skin, wash immediately with plenty of water. Gently and thoroughly wash the contaminated skin with running water and non-abrasive soap. Be particularly careful to clean folds, crevices, creases and groin. Cover the irritated skin with an emollient. If irritation persists, seek medical attention. Wash contaminated clothing before reusing."

Unfortunately, the MSDS says little about ecological hazards. Whatever harm may be posed ecologically by this material, it must be vanishingly small in comparison to its use in its heyday, when logwood plus iron was the most reliable black dye commercially available, before the introduction of modern synthetic dyes. Clear-cutting of Brazilian forests for logwood production undoubtedly resulted in much environmental damage. I have no idea whether logwood harvesting is currently practiced in an environmentally harmful way. [Followup: "Logwood from Aurora Silk is supposed to come from an environmentally and socially sustainable project."]

As long as you are steering clear of dangerous mordants such as hexavalent chromium (potassium dichromate,

a

known human carcinogen) or tin, you will probably be safe enough with quite

ordinary precautions. Always wear a properly-fitting dust mask or respirator

when working with dye powder; never reuse dyepots or other implements for food;

wear a lab coat or apron to protect clothing, goggles to protect the eyes if

splashing is possible, and always wear reliable gloves while dyeing. (Some

advise against the use of a dust mask, recommending only a NIOSH-approved toxic

dust respirator.) I do not feel that these precautions are sufficient for

working with chrome mordants, which are far too unsafe, in my opinion, for use

in the home dye studio. Hematein is not nearly as hazardous as a chrome mordant.

Prechromed synthetic dyes are safer than chrome mordant because smaller

quantities of chromium are involved, and (more importantly) because they are in

the much safer trivalent form of chromium.

a

known human carcinogen) or tin, you will probably be safe enough with quite

ordinary precautions. Always wear a properly-fitting dust mask or respirator

when working with dye powder; never reuse dyepots or other implements for food;

wear a lab coat or apron to protect clothing, goggles to protect the eyes if

splashing is possible, and always wear reliable gloves while dyeing. (Some

advise against the use of a dust mask, recommending only a NIOSH-approved toxic

dust respirator.) I do not feel that these precautions are sufficient for

working with chrome mordants, which are far too unsafe, in my opinion, for use

in the home dye studio. Hematein is not nearly as hazardous as a chrome mordant.

Prechromed synthetic dyes are safer than chrome mordant because smaller

quantities of chromium are involved, and (more importantly) because they are in

the much safer trivalent form of chromium.Many dyers believe all natural dyes to be completely safe, but in fact this is often not the case. Besides hematein, there are other toxic natural dyes as well. For example, the dyes alizarin and purpurin, derived from madder, are associated with kidney damage in animal experiments. Lily-of-the-valley, sometimes used for a pale green, is certainly toxic, as is bloodroot. The leaves of rhubarb contain toxic oxalic acid. Even relatively non-toxic dyes such as cochineal are associated with allergies, especially among the workers who prepare them. However, I think that all of these are unlikely to be a problem for the careful dyer, who takes appropriate precautions and does not do anything that will result in breathing, eating, or otherwise consuming dyestuffs.

(Please help support this web site. Thank you.)

Thursday, November 22, 2007

backstaining of dye in batik, and unwanted pale colors in batik

Name: Mateo

Message: Hi,

I am a batik "artist" and I am writing as you you have one of the most informative sites that I have been to. The question I have for you is about staining of the white or waxed areas with other colors and the other I have for you you is about dharma's Navy blue.

1. Have you had problems with the overdye staining the white areas and also the pre dyed areas of the fabric leaving the entire batik dull and and dirty looking? If so is there a way to avoid this aside from adding more synthrapol to the boiling and final washing (yes I rinse all the shirts that I do but this has become an issue as of late, leaving me with many "dirty" or "old looking batiks").

There are two ways in which a fiber reactive dye such as Procion MX dye can back-stain fabric.

One is by having still-reactive dye in the fabric when you go to rinse it out. When this happens, the unreacted dye can get on the fabric in the wrong place and stain it

permanently by reacting with it. There is no way to solve this problem after it

happens, since the dye in the wrong places is as firmly attached as that in the

right places. The solution is to prevent this by making sure that the dye that

you have applied has fully reacted before you wash it out. Some of the dye will

have reacted with the fabric and become attached to it, while some will have

reacted with the water ("hydrolyzed") and will just have gone bad. Hydrolyzed

dye is not a threat because it cannot react. The easy way to make sure that all

your dye has reacted is to give it plenty of time; for example, if your dye

studio is at least 70°F (21°C), leave your dye reaction to run

overnight, while making sure (with either urea in the dye mixture, or plastic

over the fabric) that the dye stays moist on the fabric throughout the entire

reaction time.

happens, the unreacted dye can get on the fabric in the wrong place and stain it

permanently by reacting with it. There is no way to solve this problem after it

happens, since the dye in the wrong places is as firmly attached as that in the

right places. The solution is to prevent this by making sure that the dye that

you have applied has fully reacted before you wash it out. Some of the dye will

have reacted with the fabric and become attached to it, while some will have

reacted with the water ("hydrolyzed") and will just have gone bad. Hydrolyzed

dye is not a threat because it cannot react. The easy way to make sure that all

your dye has reacted is to give it plenty of time; for example, if your dye

studio is at least 70°F (21°C), leave your dye reaction to run

overnight, while making sure (with either urea in the dye mixture, or plastic

over the fabric) that the dye stays moist on the fabric throughout the entire

reaction time.

If your dye reaction is too cool, then it will not complete in the time alloted. You may need to take care to use warmer water, always, of course, remaining below the hot temperature at which the batik wax will soften. Water that is 90°F or 100°F (32°C or 38°C) will help speed the dye reaction without softening your wax. There are various ways to keep your dye reaction warm, but that is the subject of another article.

The other form of backstaining is caused by dye that has already hydrolyzed, so it cannot form the permanent covalent bond that holds Procion MX dye to the fabric under optimal conditions. However, the dye can still associate with the fabric, albeit more loosely, in much the same way that all-purpose dye associates with cotton. Once this has happened, the solution is HOT water. When you rinse out your dye after dyeing, you start with cool water to remove all dye auxiliaries such as soda ash or salt. After that, you should use hot water to remove the dye, at least 140°F (60°C) if possible, and soak the fabric in the hot water for a little while. Hotter water is more effective still at removing excess unattached dye. A fairly short washing in nearly-boiling water will remove excess unattached Procion MX dye very effectively. This should be happening already when you boil out your wax after you are done batiking, shouldn't it?

There can be added complications that make it

harder to wash out dye. If the water is hard, the hardness minerals can form

complexes with the dyes which are much more difficult to wash out. In this case,

add a small amount of sodium hexametaphosphate to the water for every step of

dyeing, even the dye wash-out stage if necessary. See my FAQ on "We have very hard water.

Should I use distilled or spring water instead of tap

water?".

it

harder to wash out dye. If the water is hard, the hardness minerals can form

complexes with the dyes which are much more difficult to wash out. In this case,

add a small amount of sodium hexametaphosphate to the water for every step of

dyeing, even the dye wash-out stage if necessary. See my FAQ on "We have very hard water.

Should I use distilled or spring water instead of tap

water?".

Another complication that can make dye appear to

be difficult to wash out is the presence of sizing in the fabric. This should

not be a problem if you are starting with PFD ("prepared for dyeing") fabric. If

there is starch in the fabric, a drop of tincture of iodine, placed on the

apparently clean fabric, will reveal the presence of the starch by turning blue.

Starch is extraordinarily difficult to full remove from fabric. Even boiling

with soda ash will not do it. Starch in the fabric will react with the dye in

just the same way as the cellulose in the fabric, but will gradually wash out,

giving the appearance of poor washfastness. Never dye fabric that has been sized

with starch, and beware of other sizings as well, which may be equally

problematic for one reason or another.

to

be difficult to wash out is the presence of sizing in the fabric. This should

not be a problem if you are starting with PFD ("prepared for dyeing") fabric. If

there is starch in the fabric, a drop of tincture of iodine, placed on the

apparently clean fabric, will reveal the presence of the starch by turning blue.

Starch is extraordinarily difficult to full remove from fabric. Even boiling

with soda ash will not do it. Starch in the fabric will react with the dye in

just the same way as the cellulose in the fabric, but will gradually wash out,